GunGryphon

Jr Member

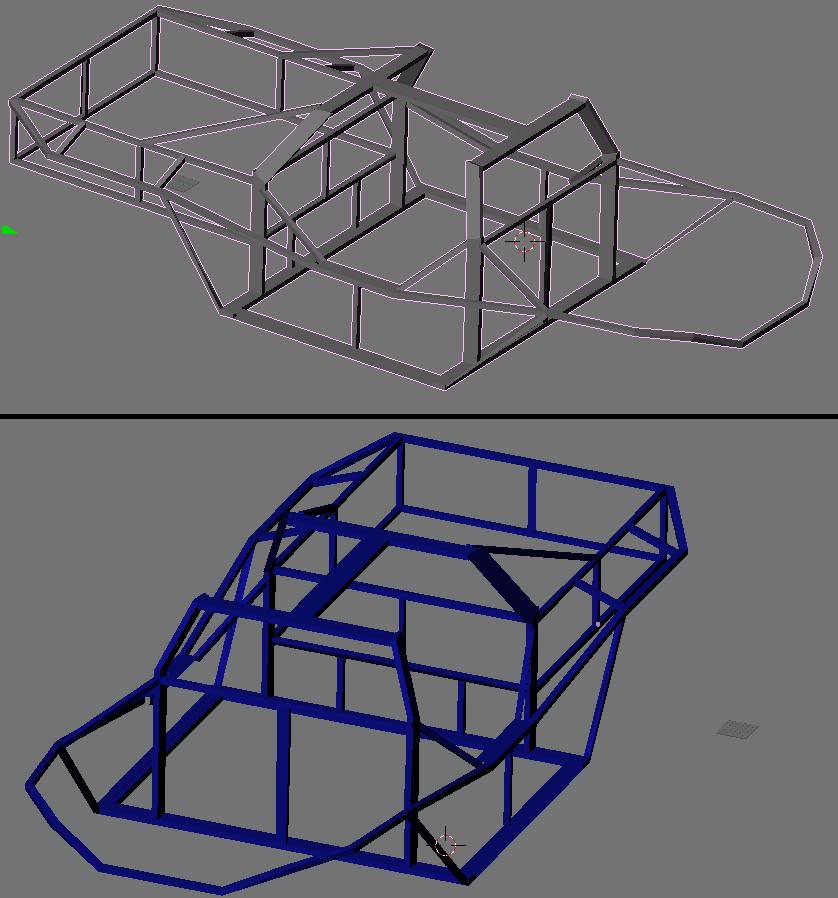

Well I do indeed have anouther question, does this 3D frame model look like it will be strong enough for road and moderate offroad usage?

The pipes are all going to be 10 gauge(1/8 in thick), with the smaller pipes being 1" square tubing while the cabin roll cage tubes are 1x3". I plan on adding plenty of supports for the outlying 1" tubes, connecting them to the frame. The total body length is 13 feet and 5 1/2 feet wide. With these specs, the body should only cost me $150.

I wish that i could start out with a vehicle, but as said earlier, I wont have the funding to buy a vehicle anytime in the next half a year. To accomodate for the variables, I'm making this so that it has high part clearances (hence why the hood looks like a ring) to accomidate for any unforseen things. And if they still arn't the right size, I can lengthen or shorten it easily (cut and weld).

Thanks for the help

-Gryphon

PS: your warthog build would classify as a specially constructed vehicle, you can read more about it here at the DMV web site

The pipes are all going to be 10 gauge(1/8 in thick), with the smaller pipes being 1" square tubing while the cabin roll cage tubes are 1x3". I plan on adding plenty of supports for the outlying 1" tubes, connecting them to the frame. The total body length is 13 feet and 5 1/2 feet wide. With these specs, the body should only cost me $150.

I wish that i could start out with a vehicle, but as said earlier, I wont have the funding to buy a vehicle anytime in the next half a year. To accomodate for the variables, I'm making this so that it has high part clearances (hence why the hood looks like a ring) to accomidate for any unforseen things. And if they still arn't the right size, I can lengthen or shorten it easily (cut and weld).

Thanks for the help

-Gryphon

PS: your warthog build would classify as a specially constructed vehicle, you can read more about it here at the DMV web site