- Member DIN

- S063

This guide is written for people who aren’t overly familiar with electronic stuff but still want to produce a high quality product.

Supplies

For all the supplies, there are many products that will work just as good, but I’ll link the ones I used for simplicity.

Overview

Generally speaking, the process is to solder a resistor onto each LED, solder these LEDs in parallel onto a wire, and connect this wire to the gutted usb cable for plugging into a power pack.

My intention is to write this guide in such a way that teaches the basics, but also encourages you to think about it yourself so that you’re able to build what makes the most sense for your suit.

Important base knowledge:

Before starting, there are a few basic things to know about the items we’ll be using.

Basic Electrical Steps:

It is recommended that you read through all the steps before starting. I recommend using 120R resistors for most LEDs.

Step 1: Prepping the LED

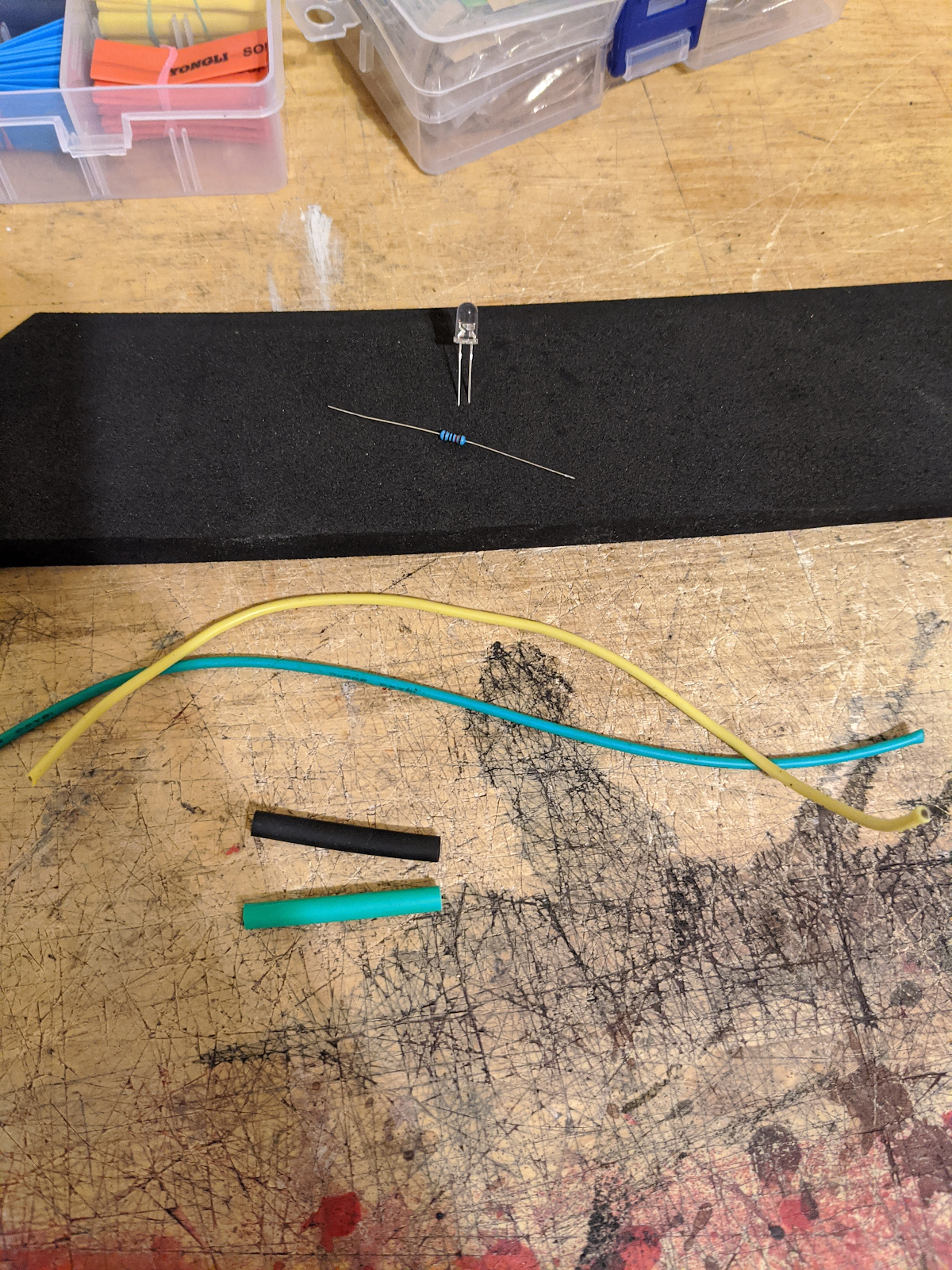

Let’s look at the first set of parts we’ll be using here:

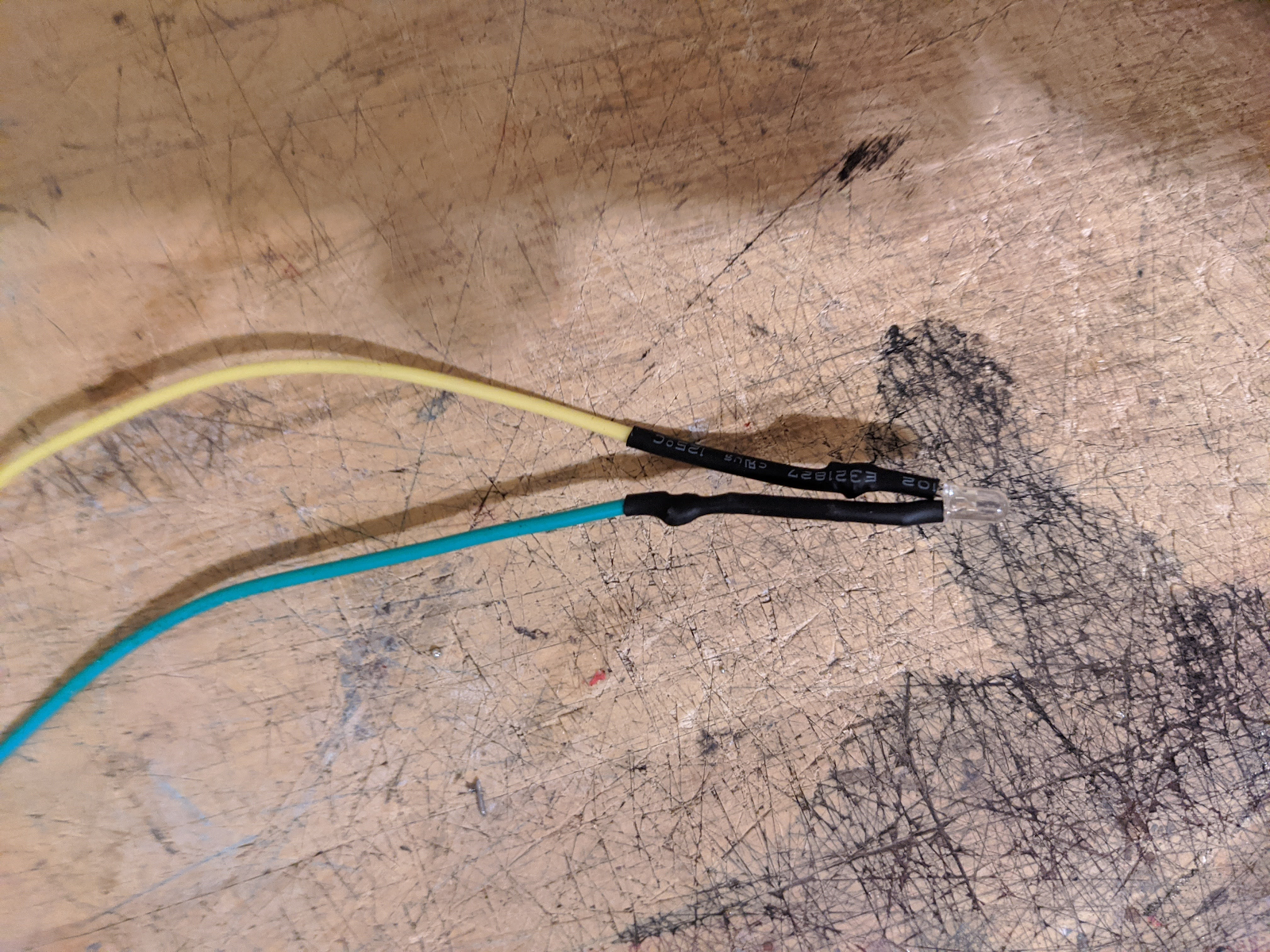

Pictured here is an LED, a 120R resistor, 2 wires (18 awg, different colors), and some shrink wrap tubes.

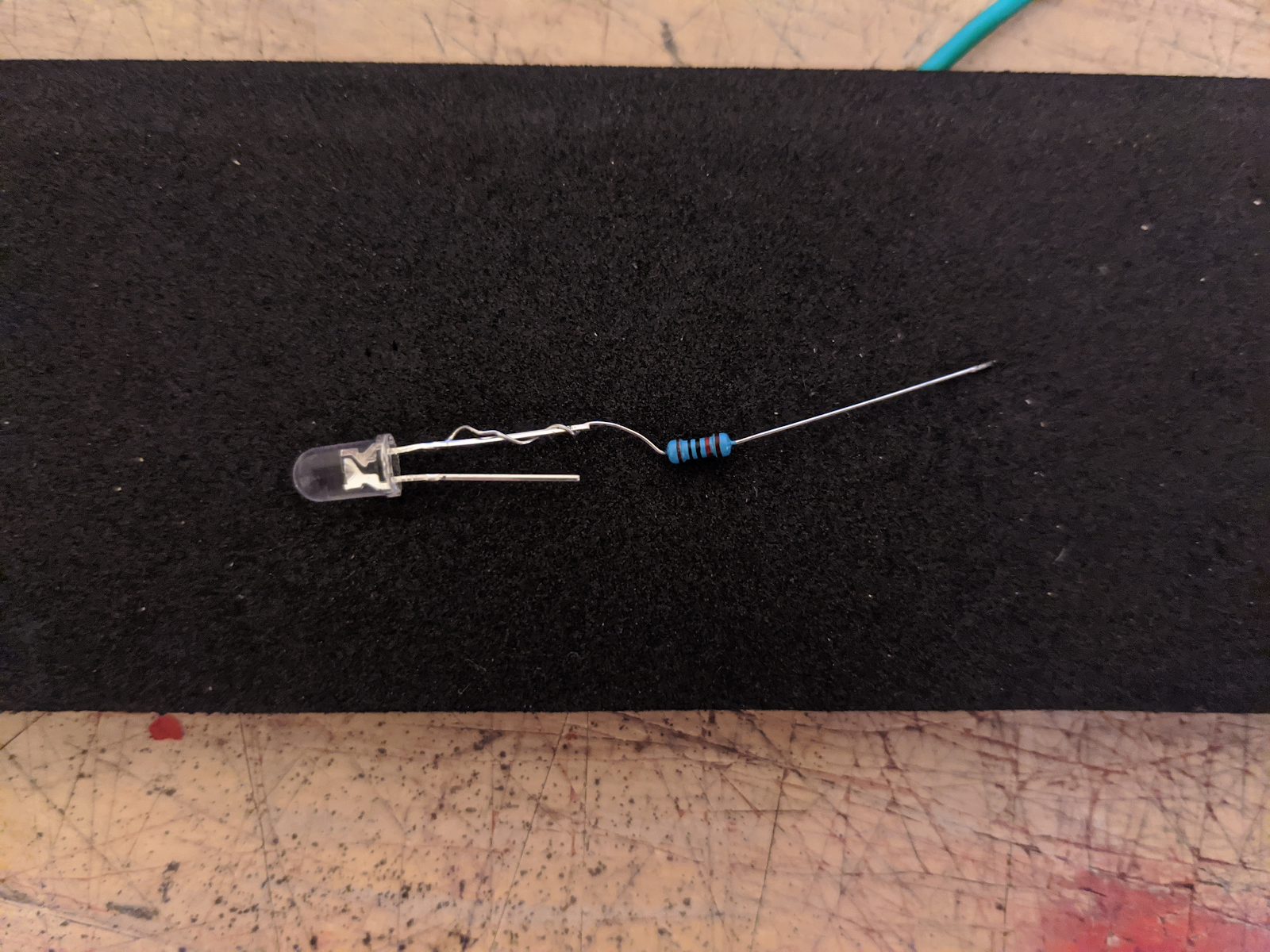

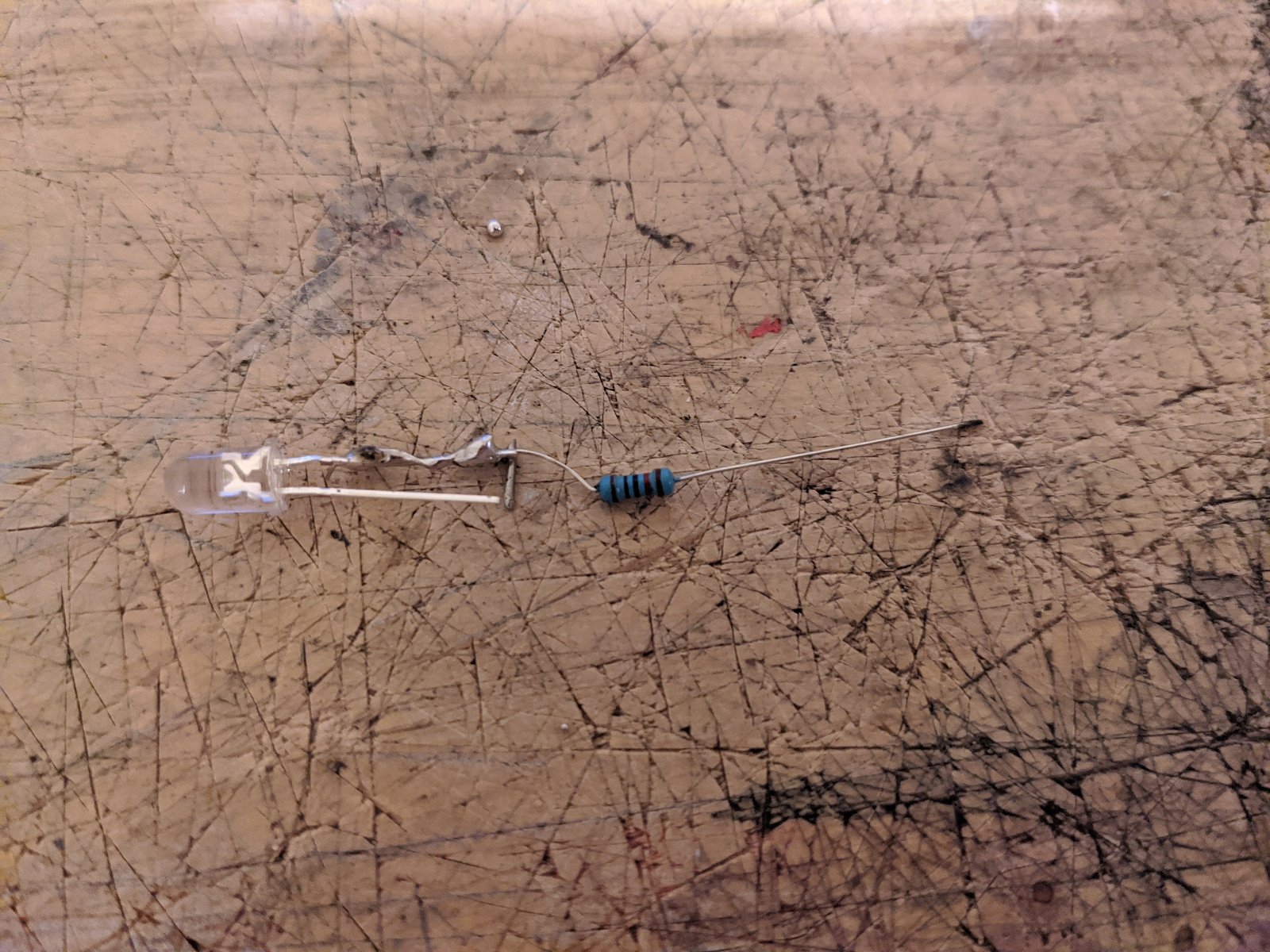

We’re going to add the resistor onto the LED. This can be a little tricky, and to help solder it on I like to wrap the resistor around the LED’s terminal before soldering. While it doesn’t technically matter whether the resistor goes on the positive or negative terminal, I like to keep it on the positive (longer) lead so that I maintain the shorter/longer relationship between positive and negative.

Once it’s wrapped, solder them together

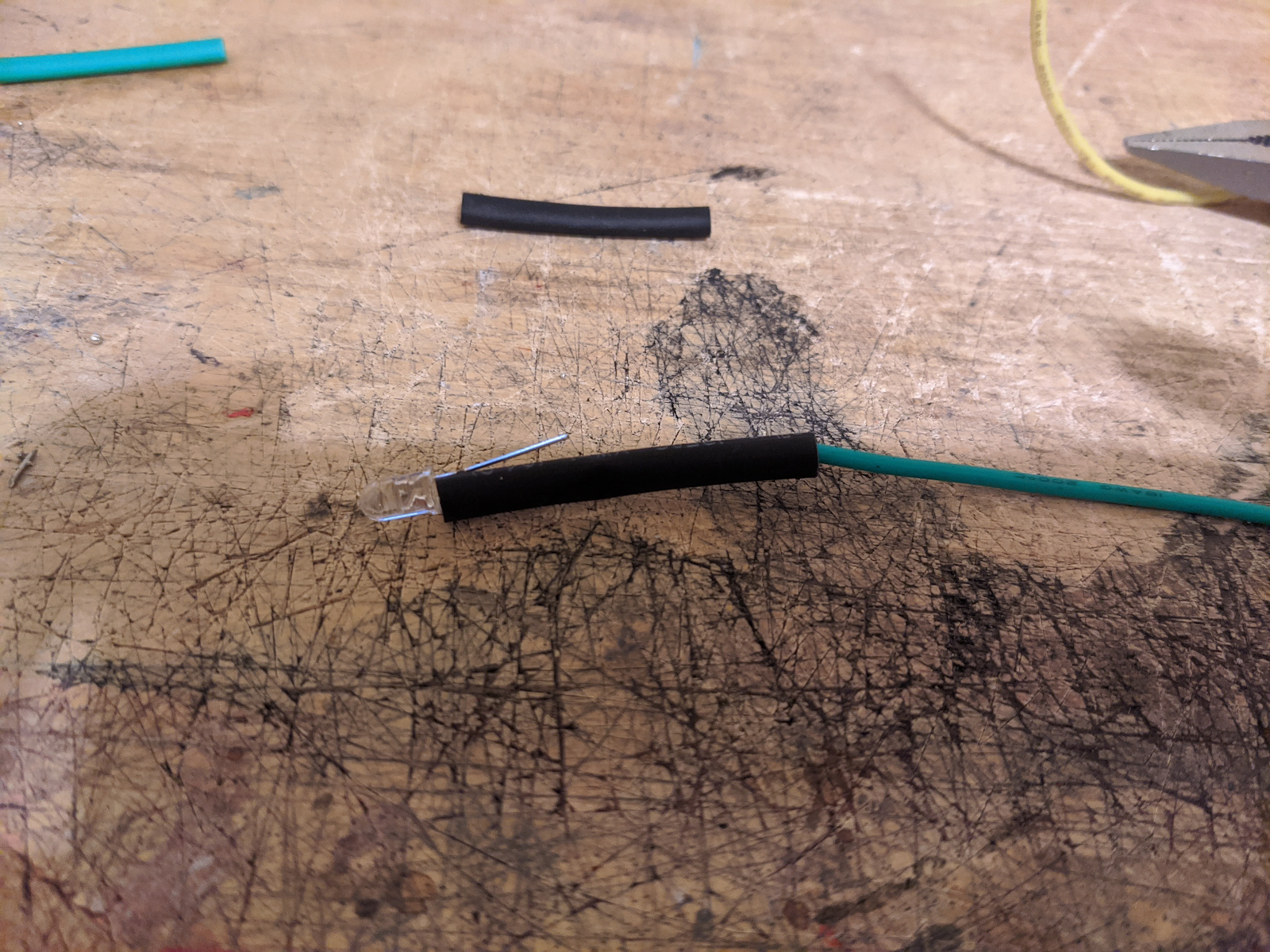

Next, solder the wire onto the other end of the resistor and shrink wrap it.

Note: To use shrink wrap, just put the tube over where you want it to be, and then heat it with your heat gun. Additionally, you may want to make sure that before you solder the wire onto the resistor, that you will be able to get the shrink wrap on. Depending on the situation, you may need to add the shrinkwrap to the wire (sliding as far from the solder joint as possible) before soldering.

Then solder the other color wire onto the other side of the LED and shrink wrap as well

The LED is now ready

Repeat this step for as many LEDs as you need.

Notes:

Step 2: Parallelize all the LEDs

Before I start this section I’ll say that this is the part where a lot of the art of wiring comes into play. In this part of the tutorial, I’m only going to focus on making an electrical circuit that works, and NOT a circuit that fits inside a costume in a way that makes sense. I’ll cover that later.

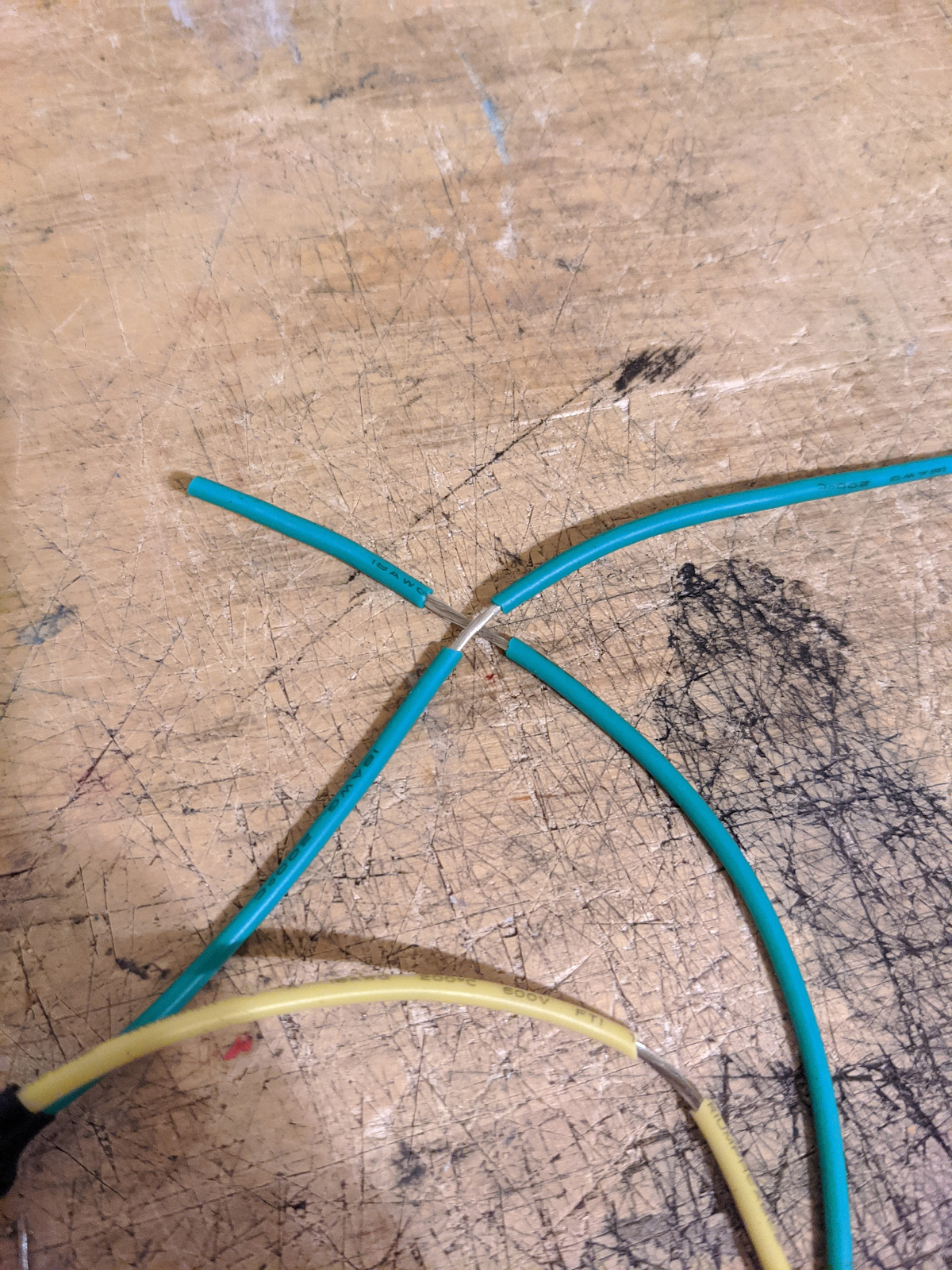

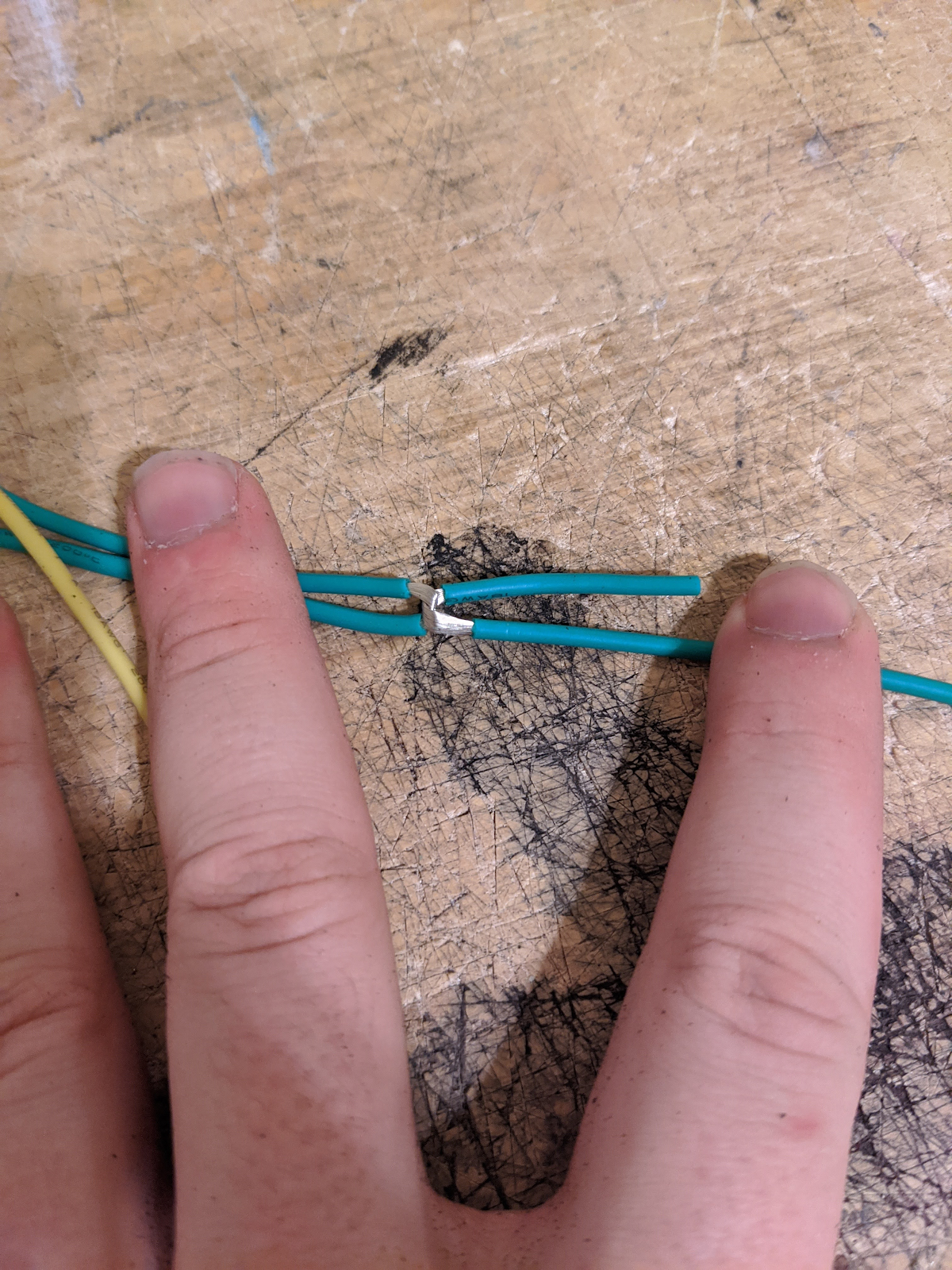

Now, to put your LEDs (however many you made) into parallel, create a stripped wire section in the middle of the LED wire (both positive and negative), and get a long length of wire for each color. Just like you’ve done before, strip a section on this long wire, we’re going to solder these together. I like to use a trick where I fold them around each other to make the connection stronger.

Note: Once again, you’ll want to think about whether you need to use the shrink wrap before or after soldering.

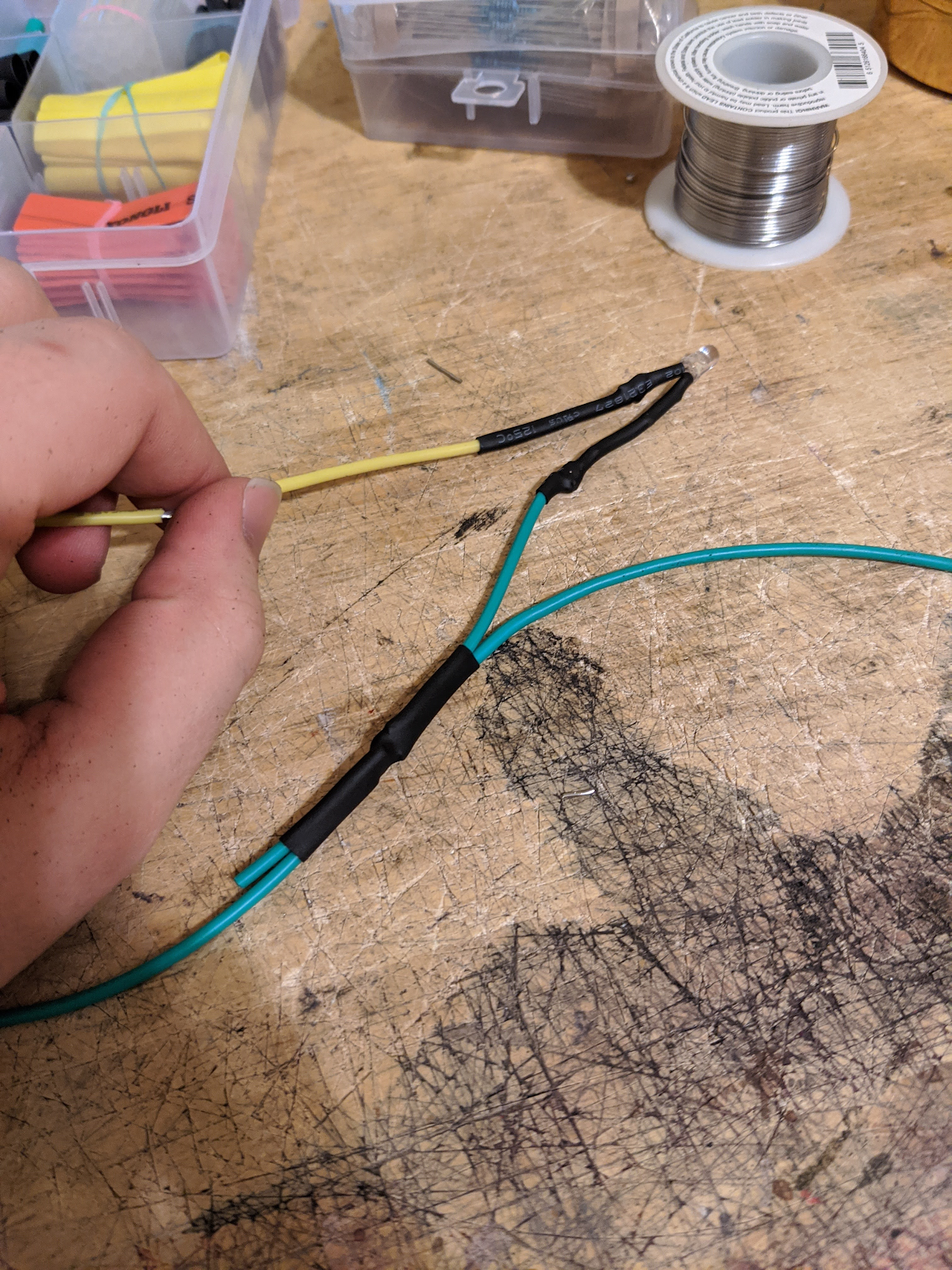

Solder these together, and shrink wrap it

Do this for both wire colors on the LED.

Repeat this for as many LEDs as you made. Just continue creating a stripped section in the long wire and soldering on the LED bundles you made.

Step 3: More Power!

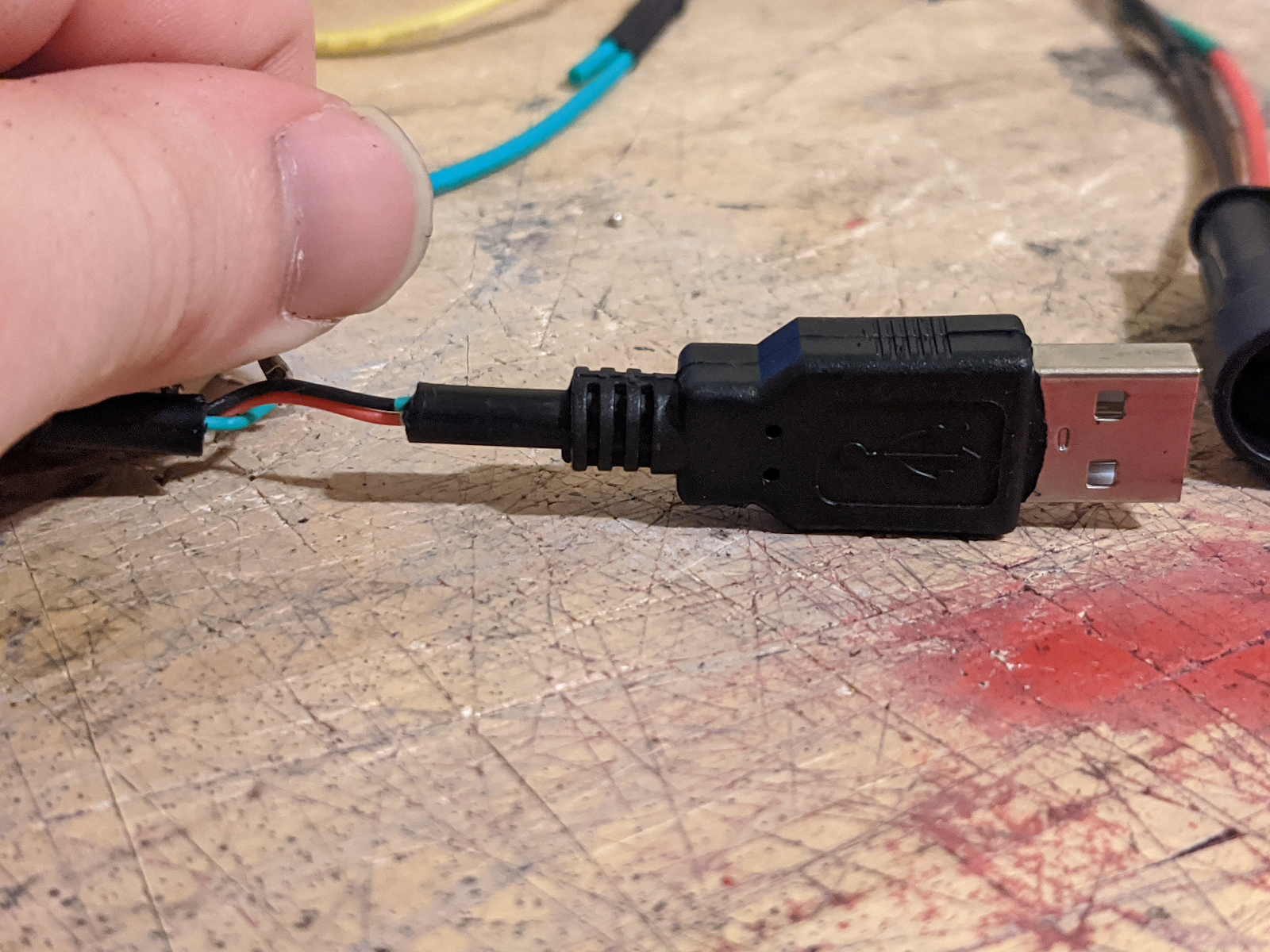

Take your USB cable and cut the non-usb type A end (type A plugs into the computer/wall charger) leaving a long usb type A cable with a bunch of wires inside it. Strip the outer protection off, and find the red and black wires. Solder the red wire to whatever wire is your positive wire, and the black wire to whatever is your negative wire. This cable can be as short or long as you want.

Shrink wrap this connection to make it stronger if you like. At this point, double check all your joints as well to make sure everything is shrink wrapped. If you missed one and can’t shrink wrap it, you can wrap it with electrical tape, though shrink wrap is better.

Assuming things went well, you should now be able to plug this into a USB power bank and have lights!

Supplies

For all the supplies, there are many products that will work just as good, but I’ll link the ones I used for simplicity.

- Resistors (only need 120 ohm): 1280 Pieces 64 Values Resistor Kit, 1% Assorted Resistors 1 Ohm-10M Ohm 1/4W Metal Film Resistors Assortment with Storage Box for DIY Projects and Experiments: Amazon.com: Industrial & Scientific

- Plugs: Amazon.com: LanHong 2 Pin Way Car Waterproof Electrical Connector Plug with Wire AWG Marine Pack of 10: Car Electronics

- Wire strippers: https://www.amazon.com/gp/product/B000OQ21CA/ref=ppx_yo_dt_b_asin_title_o04_s00?ie=UTF8&psc=1

- LEDs. Any 3-3.3v leds will work: https://www.amazon.com/gp/product/B073QMYKDM/ref=ppx_yo_dt_b_asin_title_o08_s01?ie=UTF8&psc=1

- USB power pack: https://www.amazon.com/gp/product/B012NIQG5E/ref=ppx_yo_dt_b_asin_title_o05_s00?ie=UTF8&psc=1

- Heat wrap: Ginsco 580 pcs 2:1 Heat Shrink Tube 6 Colors 11 Sizes Tubing Set Combo Assorted Sleeving Wrap Cable Wire Kit for DIY: Amazon.com: Industrial & Scientific

- Wire: https://www.amazon.com/gp/product/B073RDBW7L/ref=ppx_yo_dt_b_asin_title_o08_s01?ie=UTF8&psc=1

- HDPE: Amazon.com: HDPE (High Density Polyethylene) Sheet, Opaque Off-White, Standard Tolerance, ASTM D4976-245, 0.125" Thickness, 12" Width, 24" Length: Industrial & Scientific

- Soldering iron and solder: I already owned them.

- USB cable to butcher

Overview

Generally speaking, the process is to solder a resistor onto each LED, solder these LEDs in parallel onto a wire, and connect this wire to the gutted usb cable for plugging into a power pack.

My intention is to write this guide in such a way that teaches the basics, but also encourages you to think about it yourself so that you’re able to build what makes the most sense for your suit.

Important base knowledge:

Before starting, there are a few basic things to know about the items we’ll be using.

- LEDs are not bidirectional, that means positive must be connected to positive, and negative must be connected to negative. Otherwise, you’ll fry the LED and scare yourself.

Basic Electrical Steps:

It is recommended that you read through all the steps before starting. I recommend using 120R resistors for most LEDs.

Step 1: Prepping the LED

Let’s look at the first set of parts we’ll be using here:

Pictured here is an LED, a 120R resistor, 2 wires (18 awg, different colors), and some shrink wrap tubes.

We’re going to add the resistor onto the LED. This can be a little tricky, and to help solder it on I like to wrap the resistor around the LED’s terminal before soldering. While it doesn’t technically matter whether the resistor goes on the positive or negative terminal, I like to keep it on the positive (longer) lead so that I maintain the shorter/longer relationship between positive and negative.

Once it’s wrapped, solder them together

Next, solder the wire onto the other end of the resistor and shrink wrap it.

Note: To use shrink wrap, just put the tube over where you want it to be, and then heat it with your heat gun. Additionally, you may want to make sure that before you solder the wire onto the resistor, that you will be able to get the shrink wrap on. Depending on the situation, you may need to add the shrinkwrap to the wire (sliding as far from the solder joint as possible) before soldering.

Then solder the other color wire onto the other side of the LED and shrink wrap as well

The LED is now ready

Repeat this step for as many LEDs as you need.

Notes:

- If you have an auto stripper like the one I pictured in the overview, you can stick an led on both ends of the wires since you can connect it to power via the middle of the cable.

- Make sure to use the same color wire for your positive and negative sides. If you don’t, you will have a bad time.

Step 2: Parallelize all the LEDs

Before I start this section I’ll say that this is the part where a lot of the art of wiring comes into play. In this part of the tutorial, I’m only going to focus on making an electrical circuit that works, and NOT a circuit that fits inside a costume in a way that makes sense. I’ll cover that later.

Now, to put your LEDs (however many you made) into parallel, create a stripped wire section in the middle of the LED wire (both positive and negative), and get a long length of wire for each color. Just like you’ve done before, strip a section on this long wire, we’re going to solder these together. I like to use a trick where I fold them around each other to make the connection stronger.

Note: Once again, you’ll want to think about whether you need to use the shrink wrap before or after soldering.

Solder these together, and shrink wrap it

Do this for both wire colors on the LED.

Repeat this for as many LEDs as you made. Just continue creating a stripped section in the long wire and soldering on the LED bundles you made.

Step 3: More Power!

Take your USB cable and cut the non-usb type A end (type A plugs into the computer/wall charger) leaving a long usb type A cable with a bunch of wires inside it. Strip the outer protection off, and find the red and black wires. Solder the red wire to whatever wire is your positive wire, and the black wire to whatever is your negative wire. This cable can be as short or long as you want.

Shrink wrap this connection to make it stronger if you like. At this point, double check all your joints as well to make sure everything is shrink wrapped. If you missed one and can’t shrink wrap it, you can wrap it with electrical tape, though shrink wrap is better.

Assuming things went well, you should now be able to plug this into a USB power bank and have lights!

Last edited: