well all the armours I have made are painted and weathered. Guess I have no excuse to not make the rest. its looking to be all fibreglass armour..

Not sure if im just getting tired but Ive got no patience for foam. I have only ever managed to make very basic stuff with it. I tried again to make the shoes last night and got super frustrated so I’m gonna try and freehand some fibreglass armour as a base and then add foam details to it.. haha we shall see if that’ll work out.

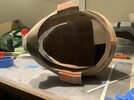

the biceps and bracers are in the fibreglassing stage. Once that’s done I’ll probably be adding foam modifications to make them more comfy, just like everything else. My old biceps were super warped so I re-pepped them and started over.

View attachment 307582

I finished the weathering with some muddy paint washes and splattering. Jun has probably had to sit around in the rain lots so I think it’s appropriate. man I love weathering.

before weathering:

View attachment 307587View attachment 307589View attachment 307591

after weathering:

View attachment 307588View attachment 307585View attachment 307584View attachment 307586View attachment 307583View attachment 307581

They still need to varnished but I’ve run out of satin finish. I’m thinking of using the liquitex varnish. Has anyone used that or is there a good slightly flexible varnish that you like? The only armour that is fully foam are the thighs and most of the belt but I don’t really want them to crack yknow?

I also bought a scout helmet file from Etsy though I’m not sure I’ll be able to print it anytime soon. I might have a local friend I could mooch off of but if that doesn’t work I’ll be using the helmet I made way back in the day. It’s a crusty nasty looking thing atm but with some tlc I bet I could get it looking good. At least until I can get a nice print.

Anyways I might actually have this mostly done before the con in sept. Excluding the lights and some of the pouches probably but it’s a huge progress for me Considering I was gonna give up on it entirely last year. And the undersuit.. ahhahaaaa… I need to remake it again. ok Byyye