I don't know how many people here are familiar with Star Trek (the Original Series in particular), but after posting this on a couple other prop forums recently and seeing the response it got, I figured I'd also post it here for everyone to see (some of the text below may seem inconsistent, as I simply copy/pasted it all from my other WiP threads elsewhere, and so all the following information actually spans almost a two-month period).

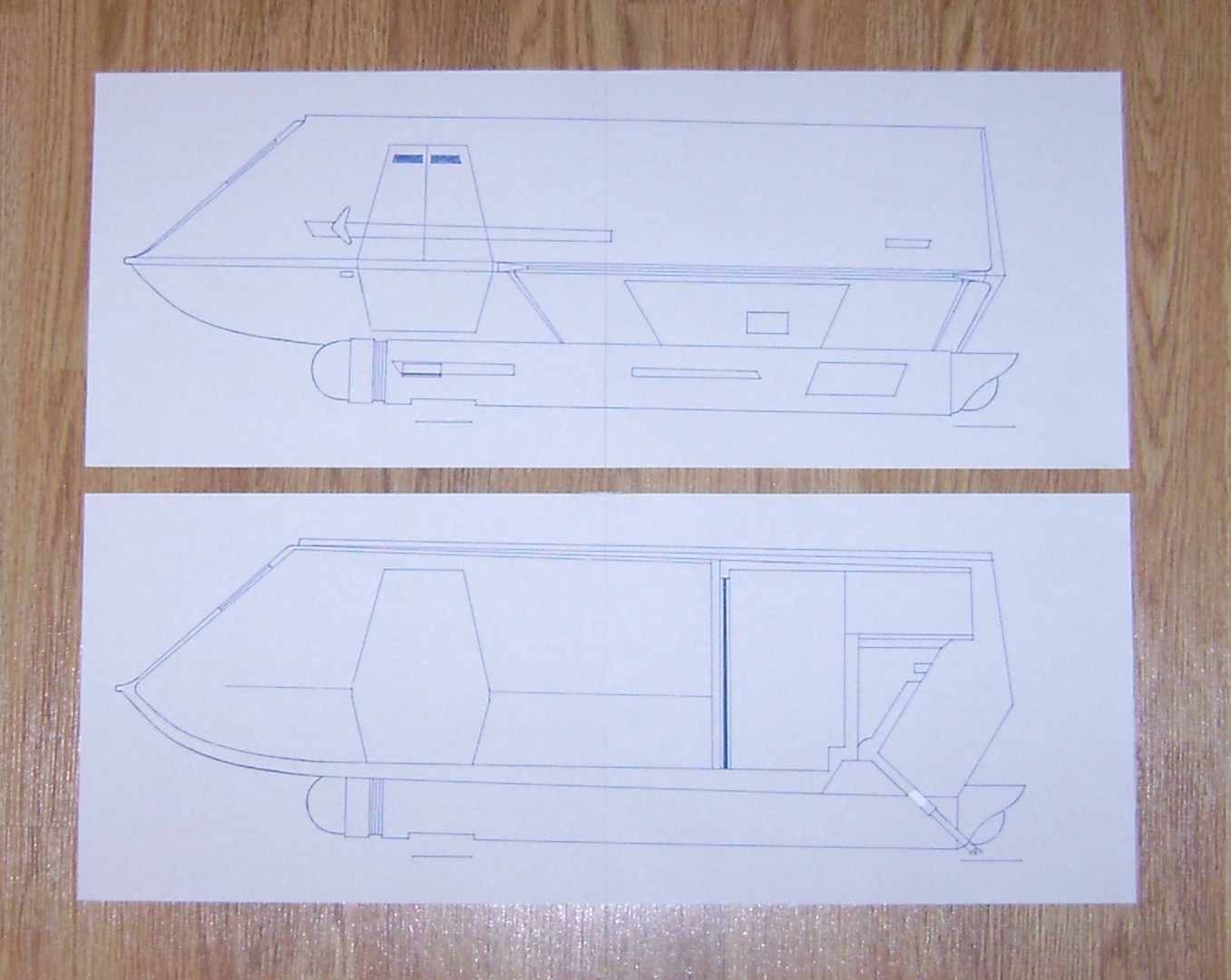

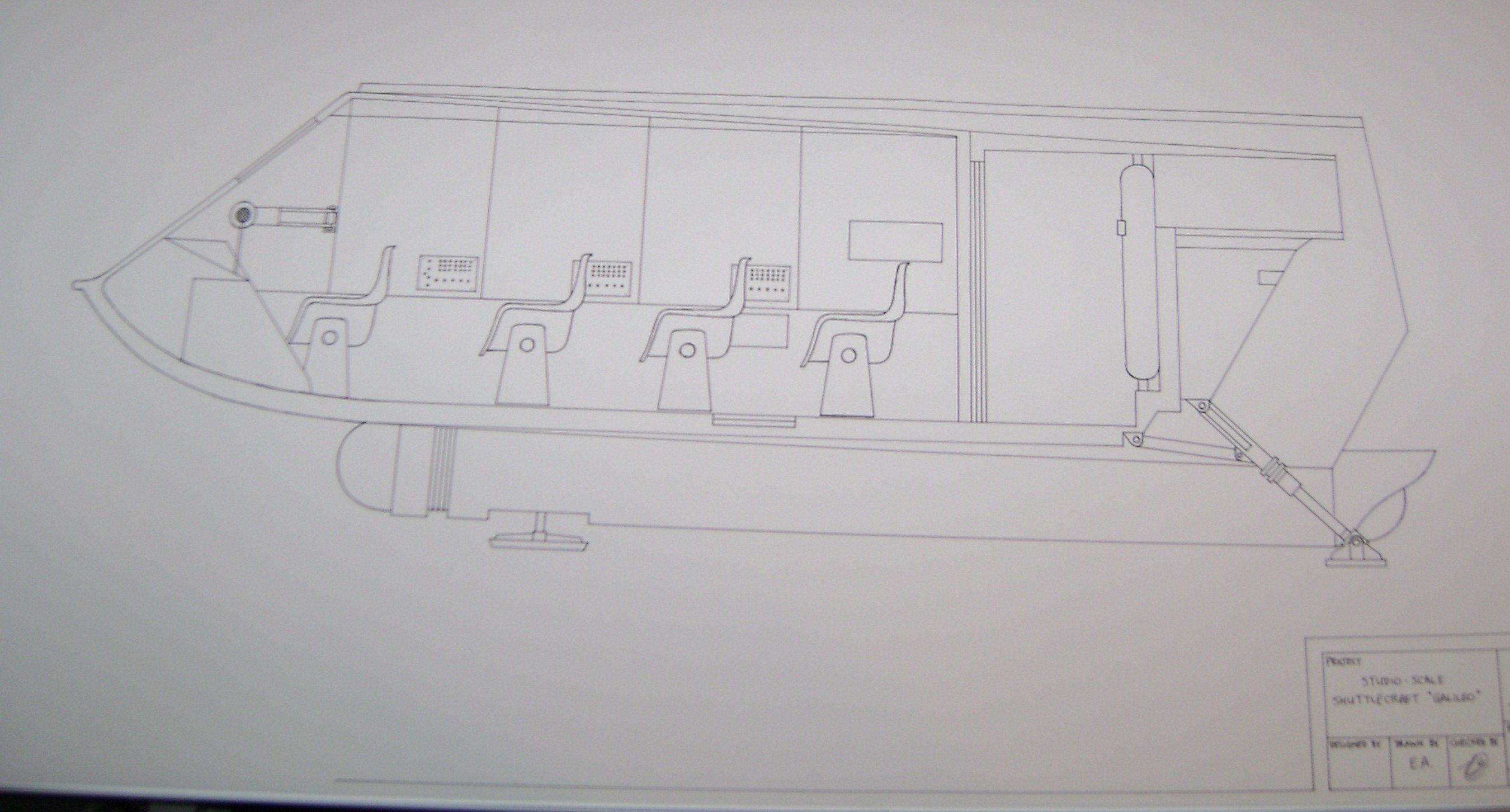

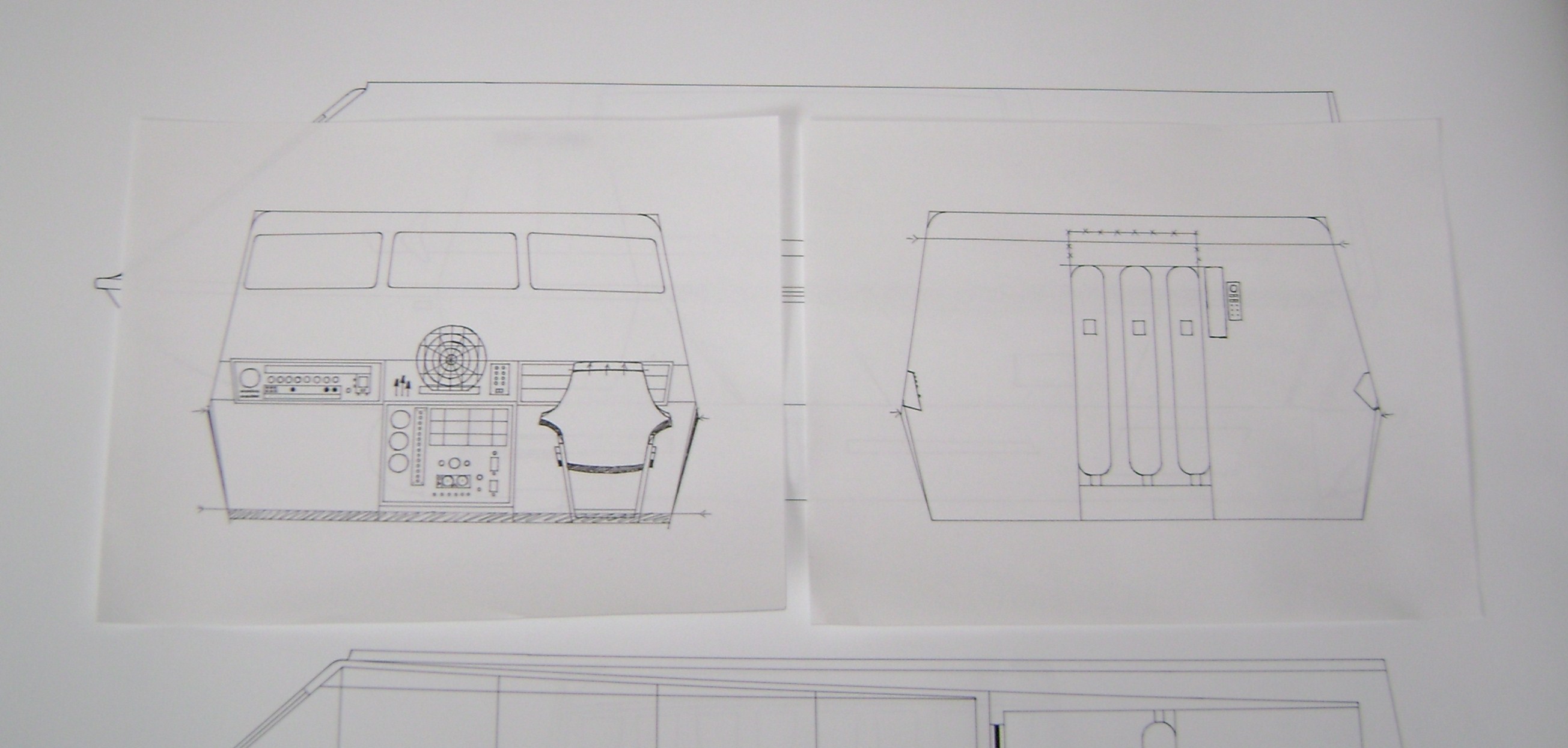

This is a large-scale model I've been wanting to scratch-build for a while now. I'd originally drawn up the following blueprint:

TOS Shuttlecraft

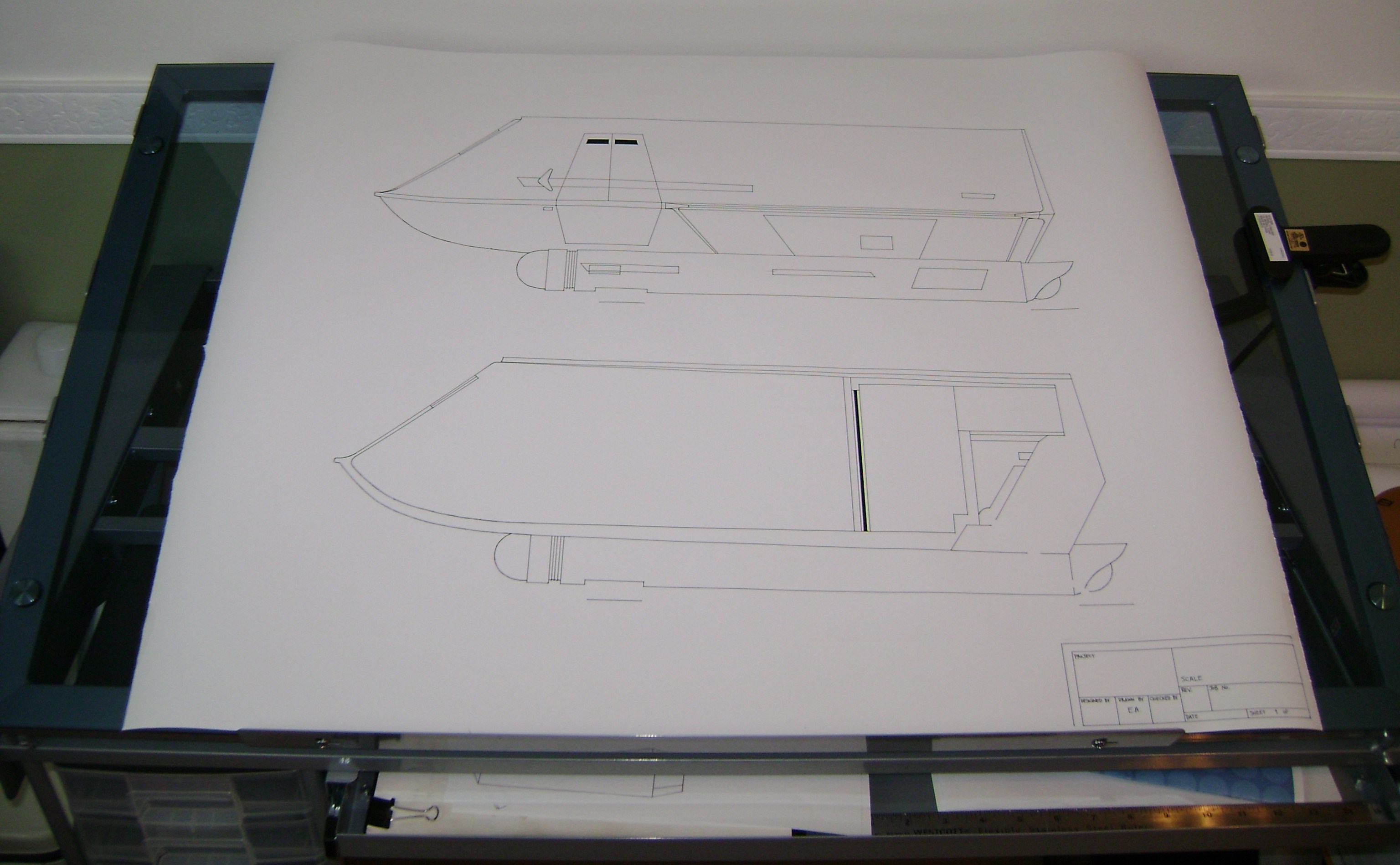

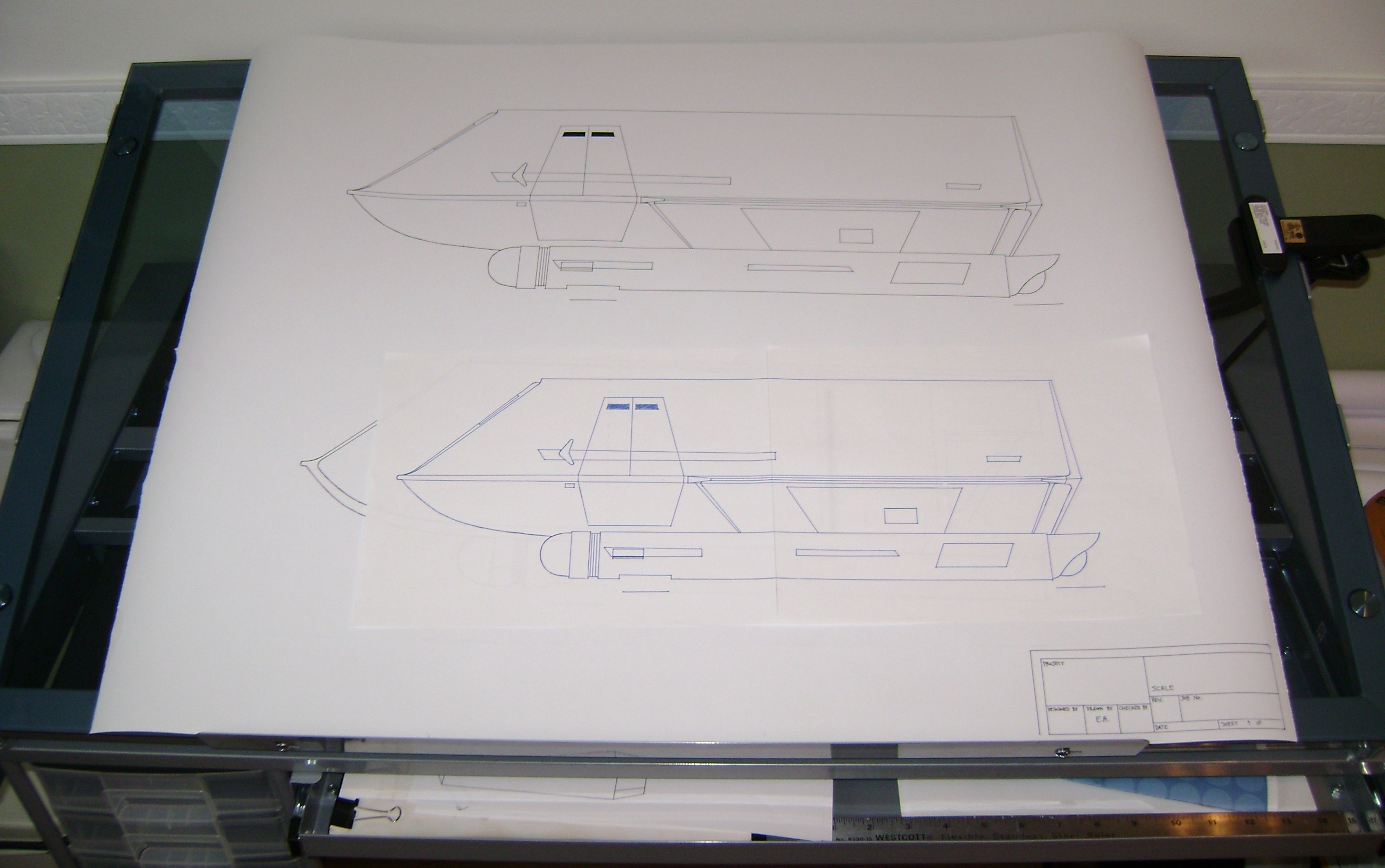

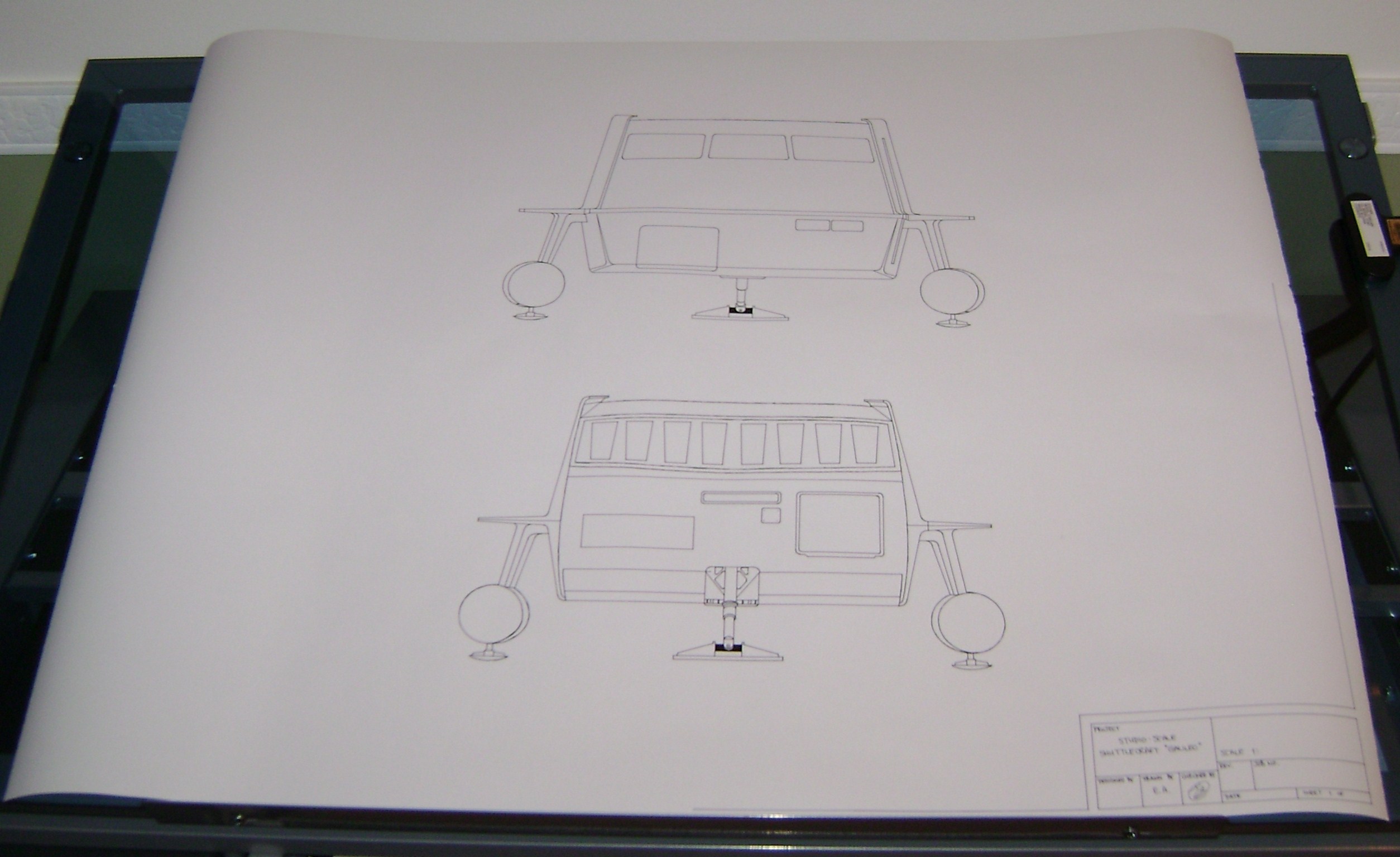

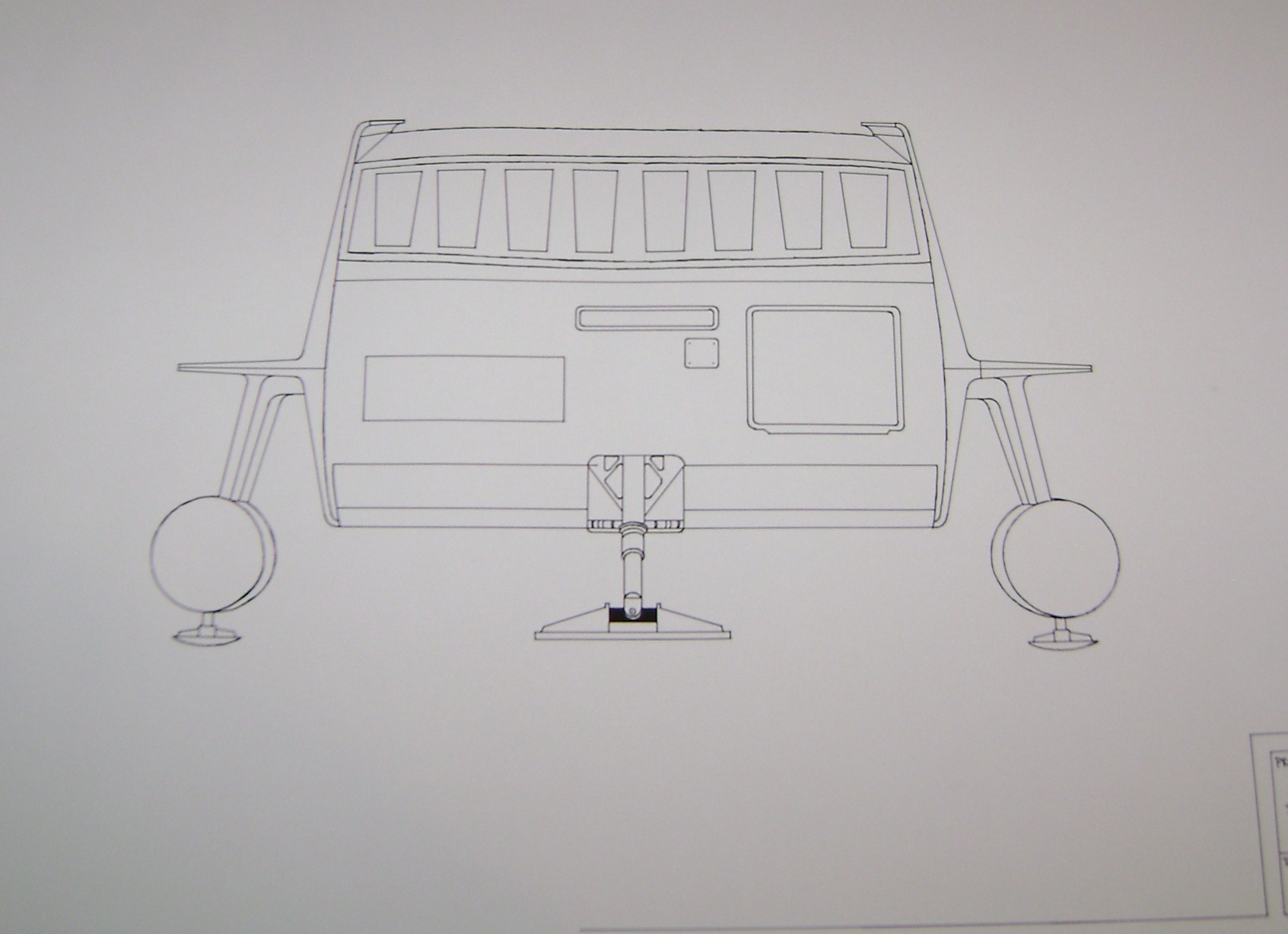

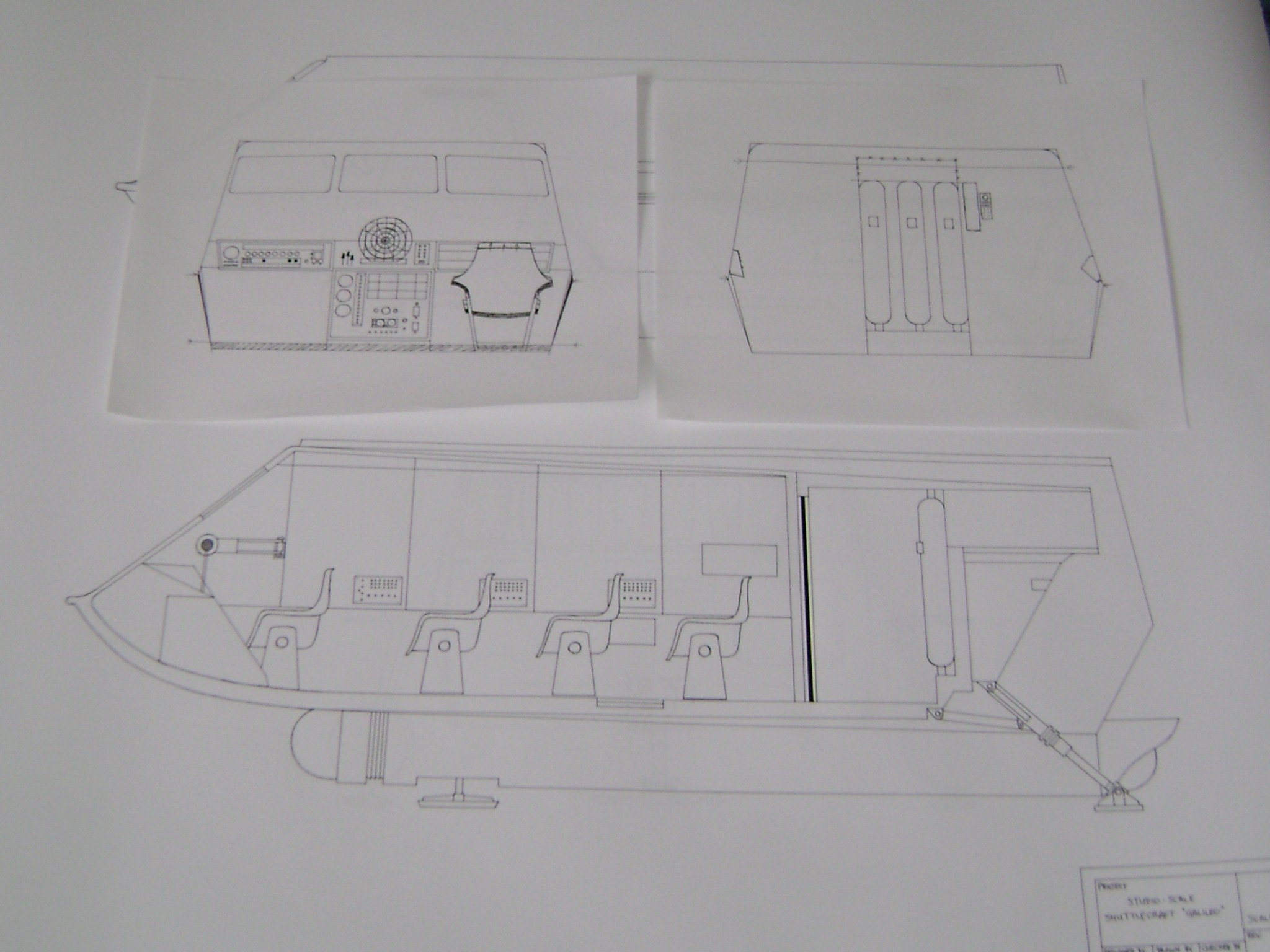

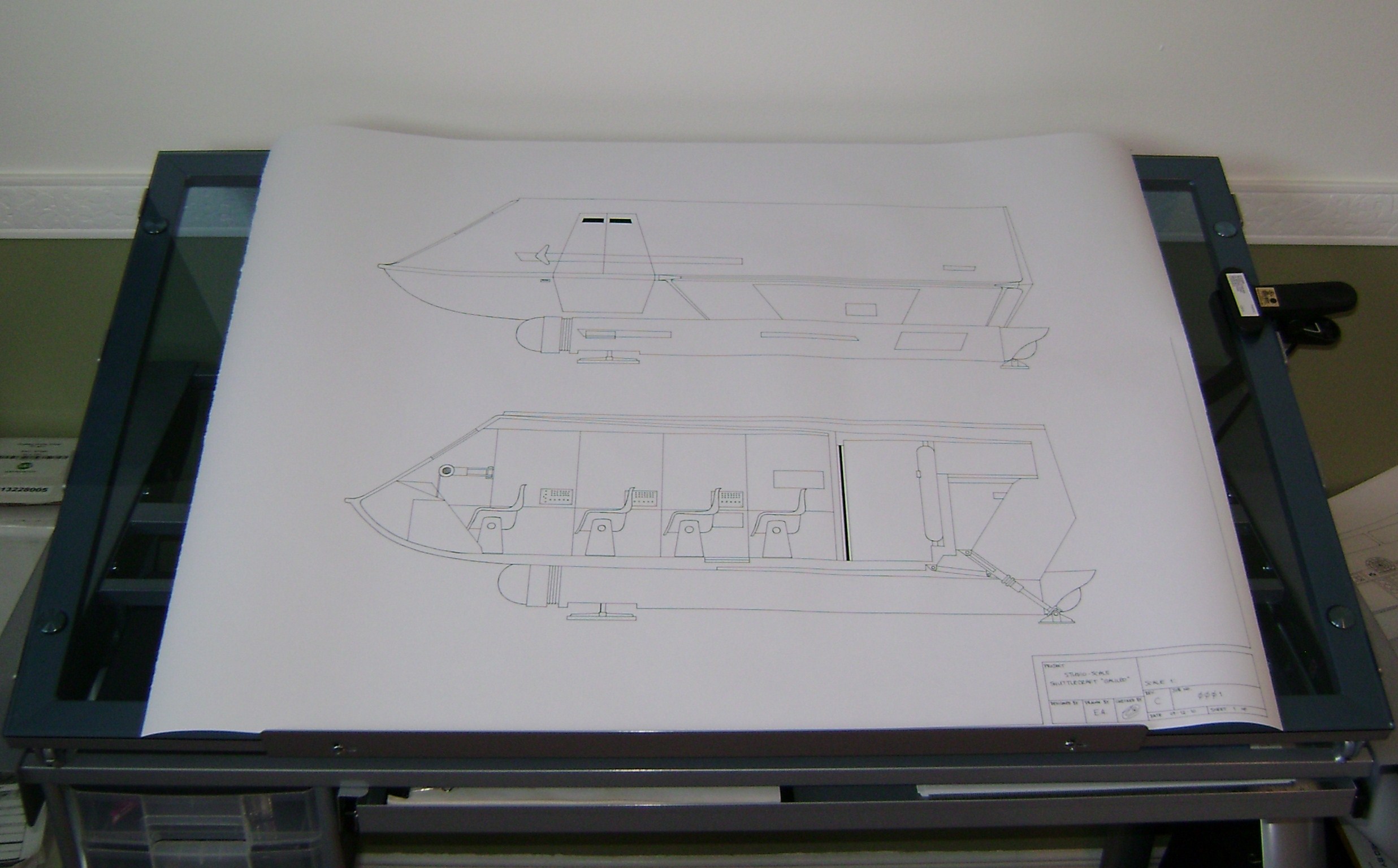

Which measures in at a whopping 18 3/4", but after some coaxing from a few folks I decided to scale it up a bit and began drafting a set of blueprints for the 22" studio-scale filming miniature:

Studio-scale TOS Shuttlecraft -- Pic 01

Studio-scale TOS Shuttlecraft -- Pic 02 (comparison to my original 18 3/4" blueprint)

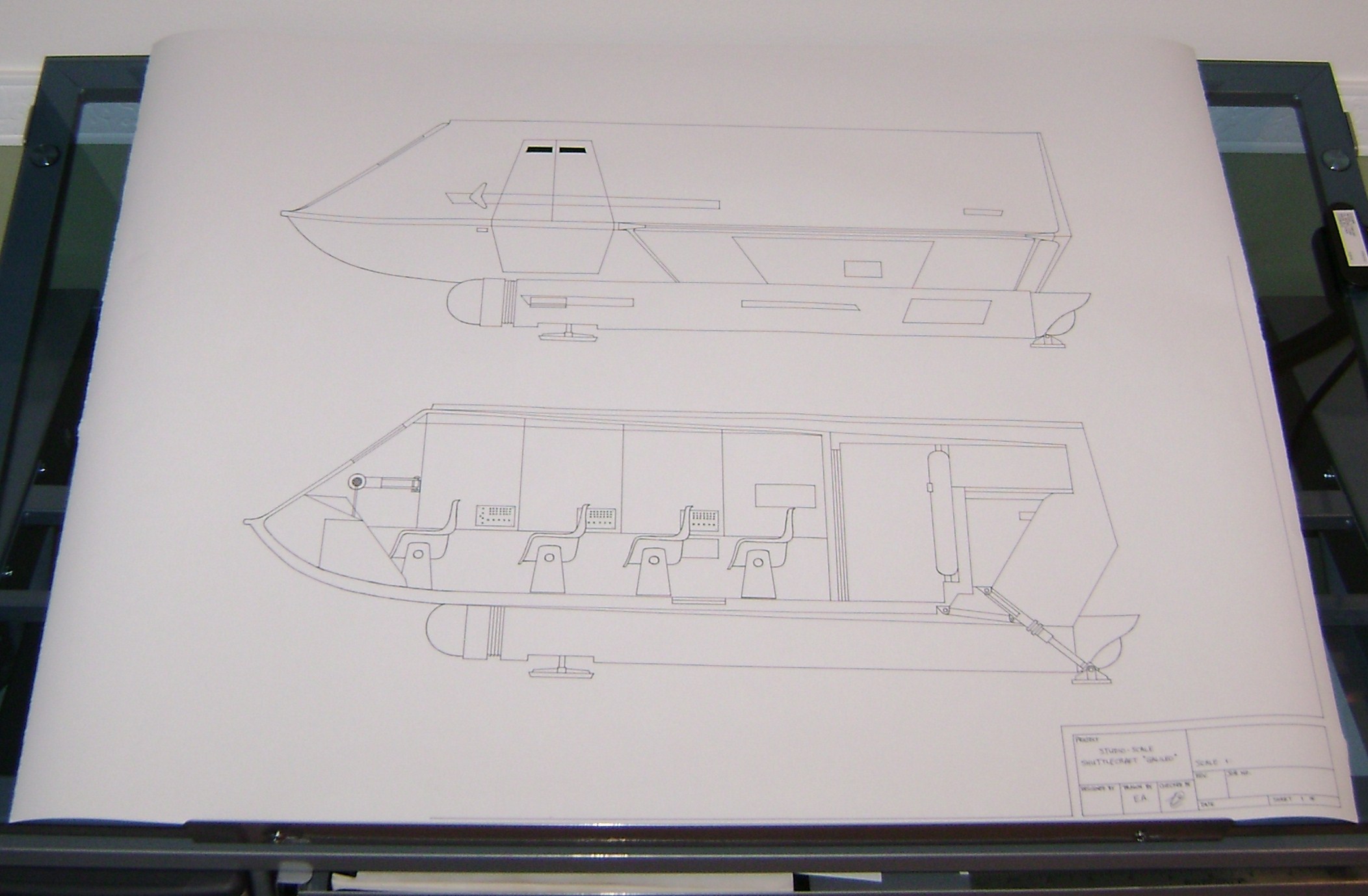

Studio-scale TOS Shuttlecraft -- Pic 03

Studio-scale TOS Shuttlecraft -- Pic 04 (close-up of interior details)

Studio-scale TOS Shuttlecraft -- Pic 05

Studio-scale TOS Shuttelcraft -- Pic 06 (close-up of rear details)

Studio-scale TOS Shuttlecraft -- Pic 07

Studio-scale TOS Shuttlecraft -- Pic 08 (close-up of interior details)

I fully intend on doing up the interior, maybe even wire it for lighting (a first for me). I was thinking perhaps I can construct the body out of sheet styrene, both the internal frame and skin, and hopefully find PVC piping of the correct diameter for the nacelles.

There are even plans in mind to mold/cast this and make it available as a fiberglass shell kit, complete with interior pieces, but more info on that as I near completion on this build.

Here is the now-final side profile for the blueprints that will be used for the build:

Studio-scale Shuttlecraft -- Pic 09

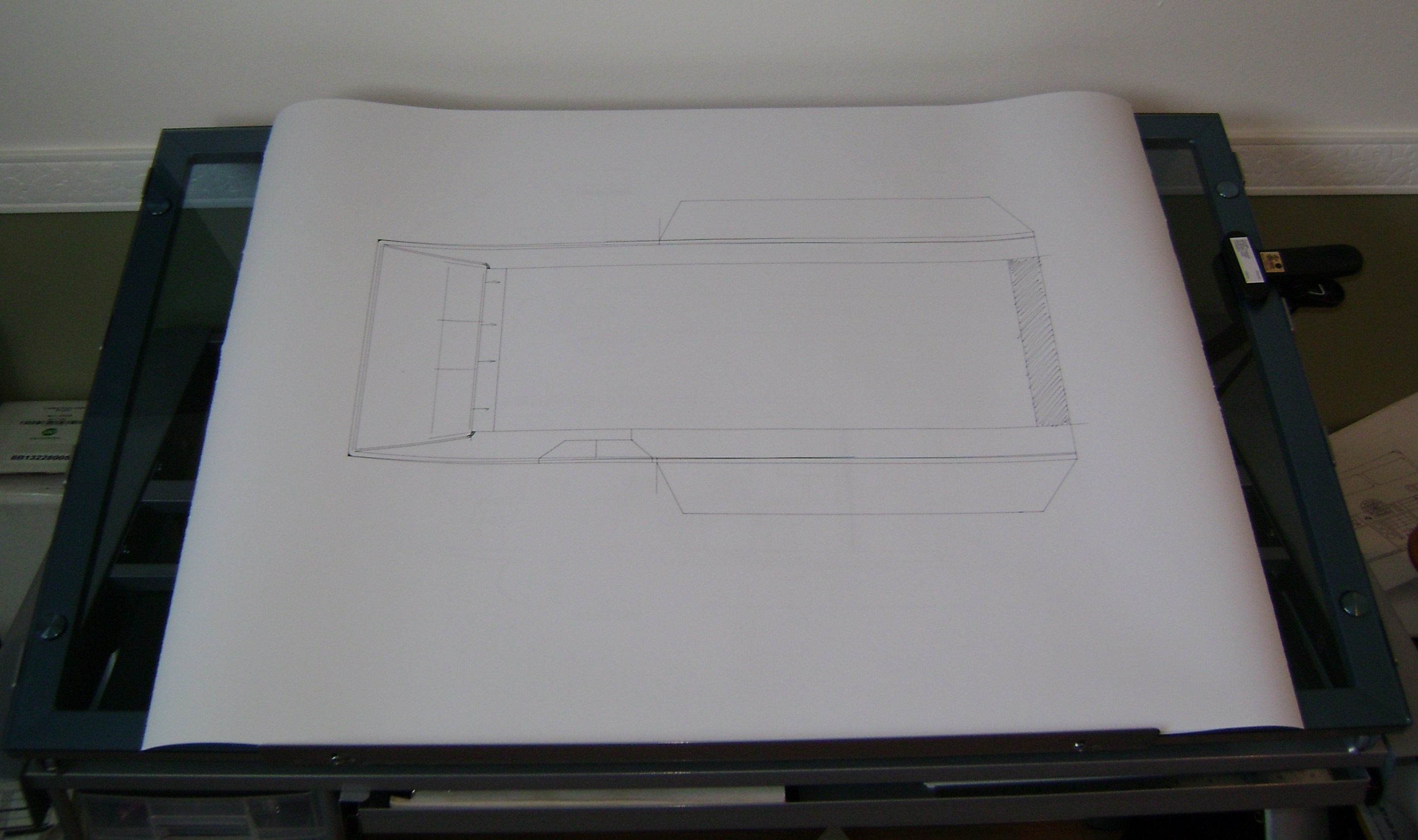

I'm still working on drafting the dorsal (top) view:

Studio-scale Shuttlecraft -- Pic 10

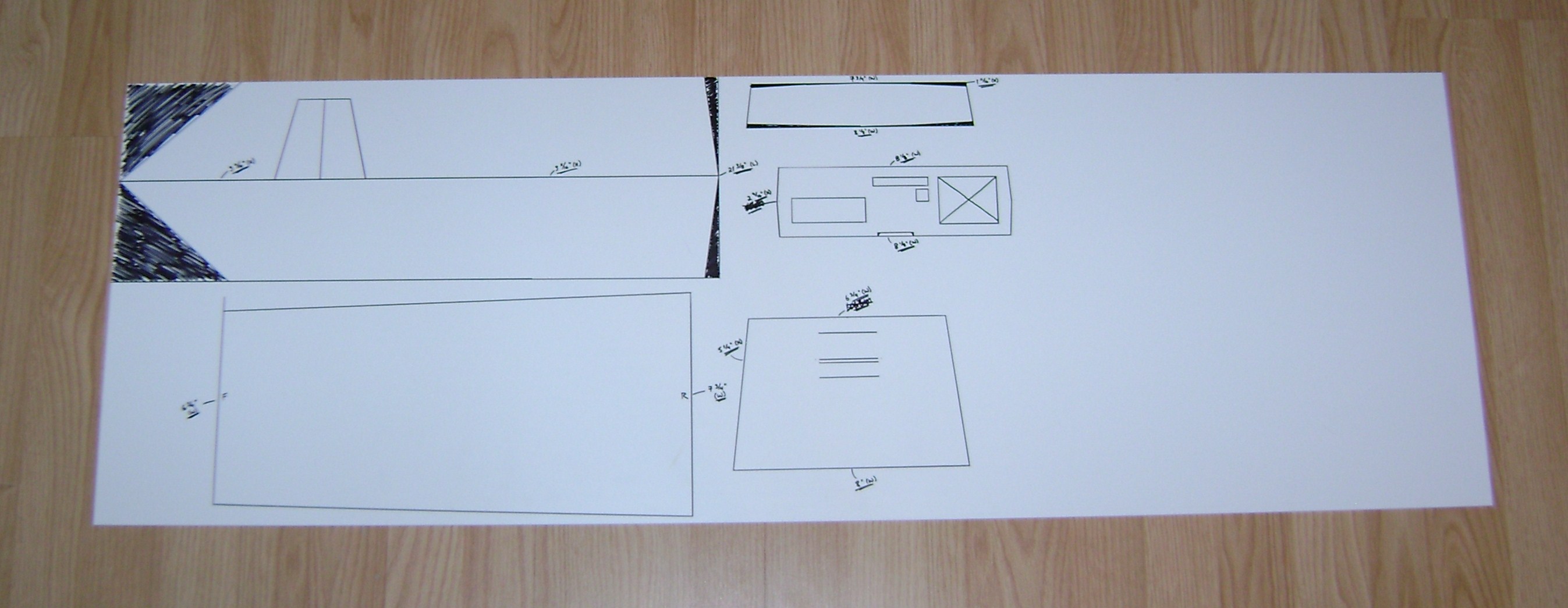

And haven't even gotten around the ventral (bottom) view, but even so I couldn't help myself and started transferring some of the measurements to some sheet styrene I bought earlier in the month:

Studio-scale Shuttlecraft -- Pic 11

So far, I've only transferred the top half of the Shuttlecraft to the styrene for cutting, but will get to the bottom half shortly. Then, I'll start scribing/cutting out the various pieces for assembly.

I went out and picked up some acrylic tubing for the nacelles, with the correct 1.5" outer diameter. Didn't even have to order online; I'd forgotten there's a shop in town here that specializes in everything plastic (sheet, tubing, etc.). I've already marked off the areas that are to be cut out -- forward landing gear, inset step -- and have begun cutting those out with my trusty Dremel tool.

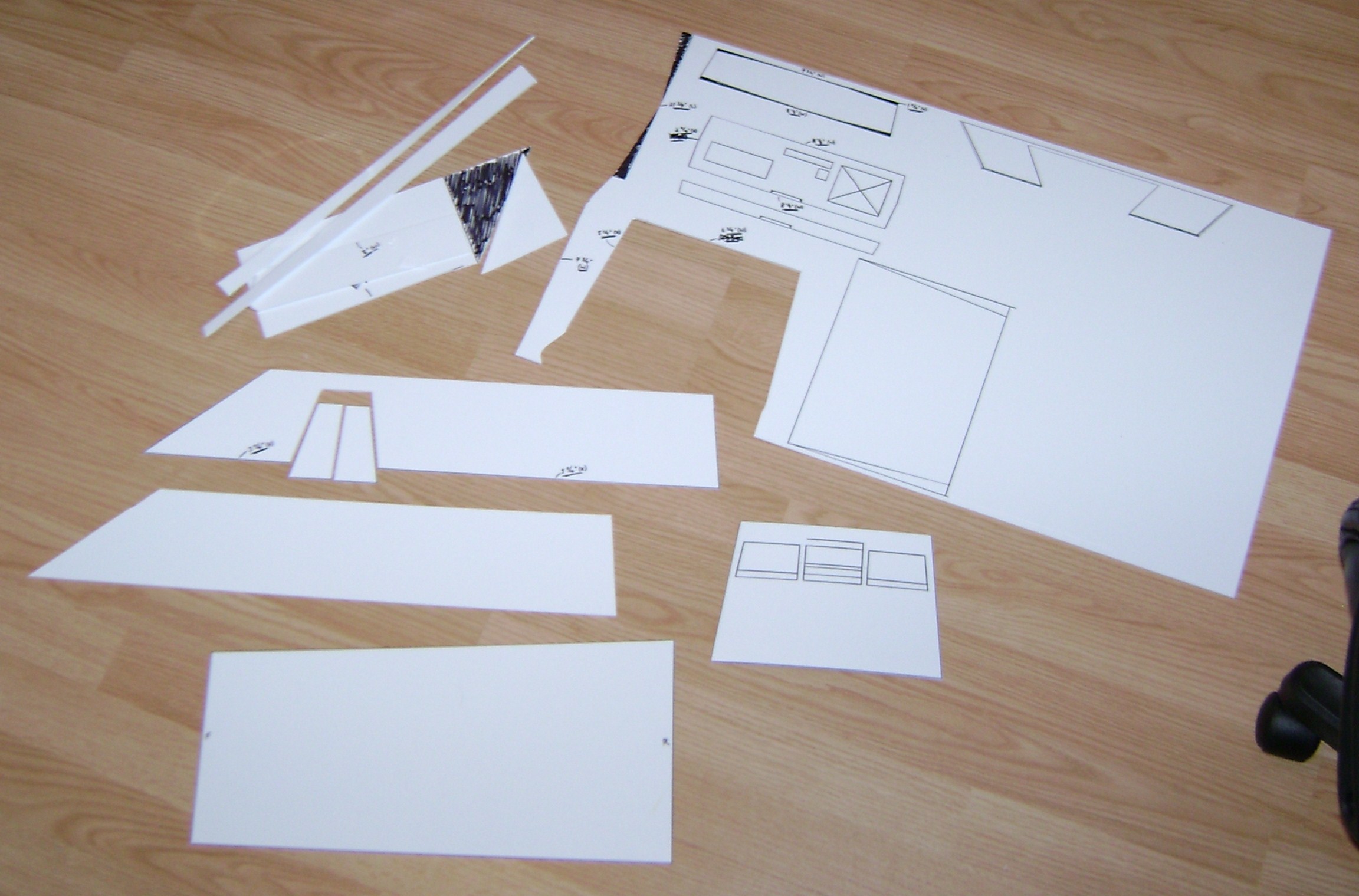

As I've now gotten that material, I also began cutting out the various parts I traced out on styrene. Here are a few progress pics:

Studio-scale Shuttlecraft -- Pic 12 (the beginnings of cutting out the pieces transferred to styrene)

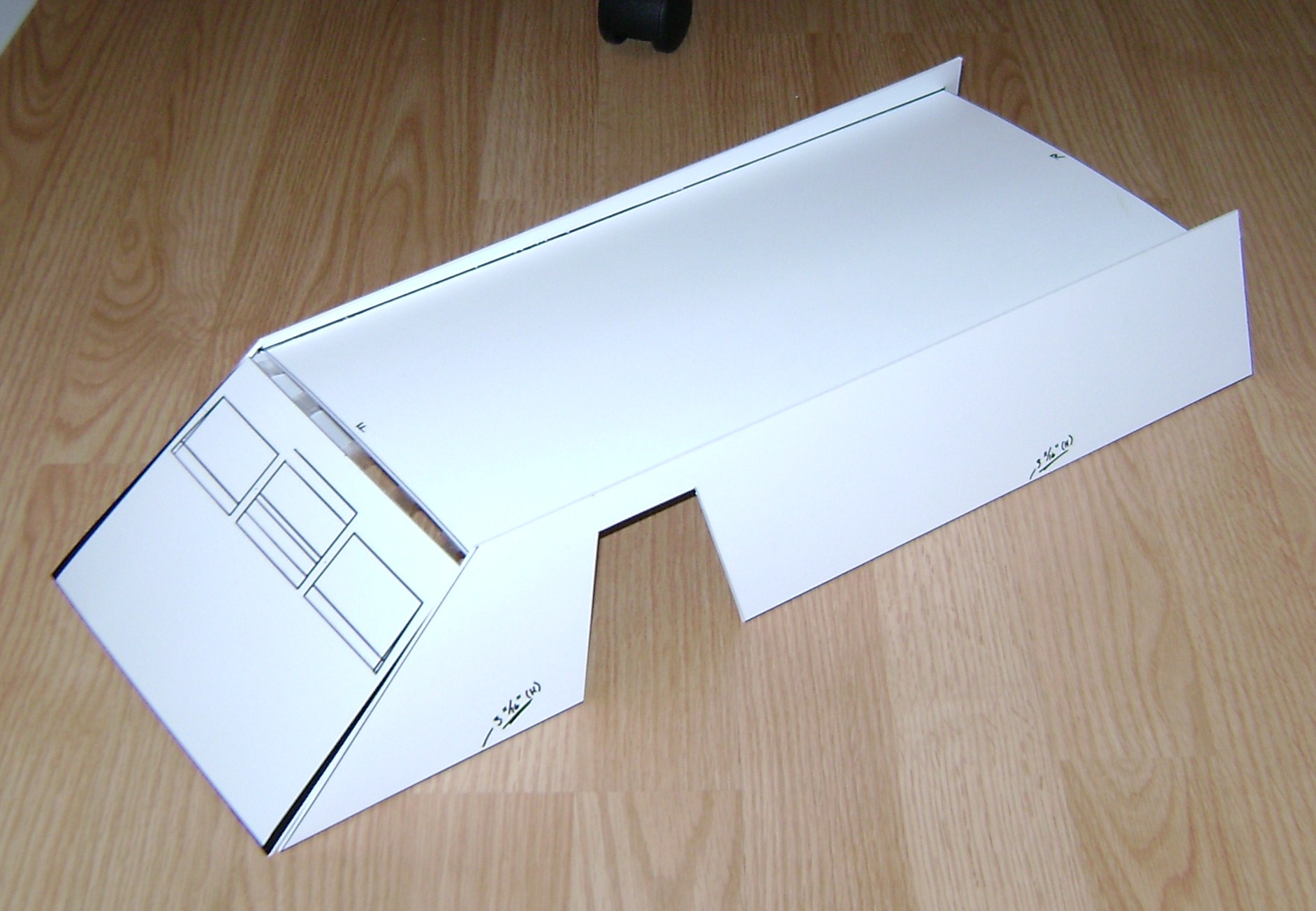

Studio-scale Shuttlecraft -- Pic 13 (at this point, I've managed to put the main parts of the upper half of the hull together; the front plate is just loosely taped in place for test fitting)

Studio-scale Shuttlecraft -- Pic 14 (wanted to see what the hatch doors would look like, so I taped them in place just to get an idea)

This is a large-scale model I've been wanting to scratch-build for a while now. I'd originally drawn up the following blueprint:

TOS Shuttlecraft

Which measures in at a whopping 18 3/4", but after some coaxing from a few folks I decided to scale it up a bit and began drafting a set of blueprints for the 22" studio-scale filming miniature:

Studio-scale TOS Shuttlecraft -- Pic 01

Studio-scale TOS Shuttlecraft -- Pic 02 (comparison to my original 18 3/4" blueprint)

Studio-scale TOS Shuttlecraft -- Pic 03

Studio-scale TOS Shuttlecraft -- Pic 04 (close-up of interior details)

Studio-scale TOS Shuttlecraft -- Pic 05

Studio-scale TOS Shuttelcraft -- Pic 06 (close-up of rear details)

Studio-scale TOS Shuttlecraft -- Pic 07

Studio-scale TOS Shuttlecraft -- Pic 08 (close-up of interior details)

I fully intend on doing up the interior, maybe even wire it for lighting (a first for me). I was thinking perhaps I can construct the body out of sheet styrene, both the internal frame and skin, and hopefully find PVC piping of the correct diameter for the nacelles.

There are even plans in mind to mold/cast this and make it available as a fiberglass shell kit, complete with interior pieces, but more info on that as I near completion on this build.

Here is the now-final side profile for the blueprints that will be used for the build:

Studio-scale Shuttlecraft -- Pic 09

I'm still working on drafting the dorsal (top) view:

Studio-scale Shuttlecraft -- Pic 10

And haven't even gotten around the ventral (bottom) view, but even so I couldn't help myself and started transferring some of the measurements to some sheet styrene I bought earlier in the month:

Studio-scale Shuttlecraft -- Pic 11

So far, I've only transferred the top half of the Shuttlecraft to the styrene for cutting, but will get to the bottom half shortly. Then, I'll start scribing/cutting out the various pieces for assembly.

I went out and picked up some acrylic tubing for the nacelles, with the correct 1.5" outer diameter. Didn't even have to order online; I'd forgotten there's a shop in town here that specializes in everything plastic (sheet, tubing, etc.). I've already marked off the areas that are to be cut out -- forward landing gear, inset step -- and have begun cutting those out with my trusty Dremel tool.

As I've now gotten that material, I also began cutting out the various parts I traced out on styrene. Here are a few progress pics:

Studio-scale Shuttlecraft -- Pic 12 (the beginnings of cutting out the pieces transferred to styrene)

Studio-scale Shuttlecraft -- Pic 13 (at this point, I've managed to put the main parts of the upper half of the hull together; the front plate is just loosely taped in place for test fitting)

Studio-scale Shuttlecraft -- Pic 14 (wanted to see what the hatch doors would look like, so I taped them in place just to get an idea)