flyinace54

New Member

sorry thought of the question after I had already posted

How long until i get promoted?

Like Halo95 said, it depends on the skill, but it also depends on your dedication.

Traditionally, you'll be using cardstock, fiberglass and resin.

It's the middle of winter (most everywhere anyways), and resin takes a very long time to cure in the cold.

I built only a helmet, learned a lot, and devoted over forty working hours just to resining and detailing it, making sure it was perfect. This, added to my strict schedule I already had, made it take me about two months from pep to wiring for lights. I didn't make any time-consuming mistakes (improper pep sizing or badly mixed resin) and it was my first one.

Just take your time and do it right. If you rush it, a good one will only take longer.

that depends on a few things... one being is the helmet a pep helmet? if it is then you should just be able to make the pep visor and use that as a template to measure out your materials, always make sure that its bigger than the actual visor so its easier to fit in.I was making a helmet, and i have flexable material for the visor, but i dont want to waste any. Does anyone know how you would fing out what size to make the visor?

Go to the Molded Armor section and look for a sticky called Dual-Layer Visor mini-tutorial.Please someone help! I have been looking for a long time and I can't seem to find any good video's or explanations on how to even start on the face shield for a halo helmet or any helmet for that matter. I know to obviously get a face shield, measure the face shield, but would I use a dremel to shape it or what do i use to shape it? Thats about it, any other advice would be very helpful.

that depends on a few things... one being is the helmet a pep helmet? if it is then you should just be able to make the pep visor and use that as a template to measure out your materials, always make sure that its bigger than the actual visor so its easier to fit in.

ironicaly (i have no clue how to spell that) it is a pep helmet, bu it is the LD recon helmet in the all in one pack, it does not have a pep visor, and there is a sort of brace on the inside that keeps me from making the visor bigger than usual to make a good fit

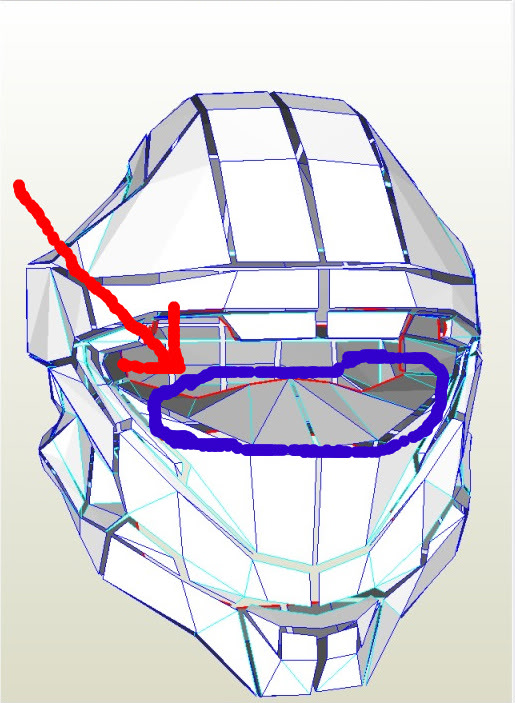

see here