- Member DIN

- S068

It's bad when the Halo builds are starting to seem like side projects. Here's some new goodies!

Who here remembers what was going on way back in that first post? Honest answers only! There's been one major piece missing from my armour somewhere in this area.

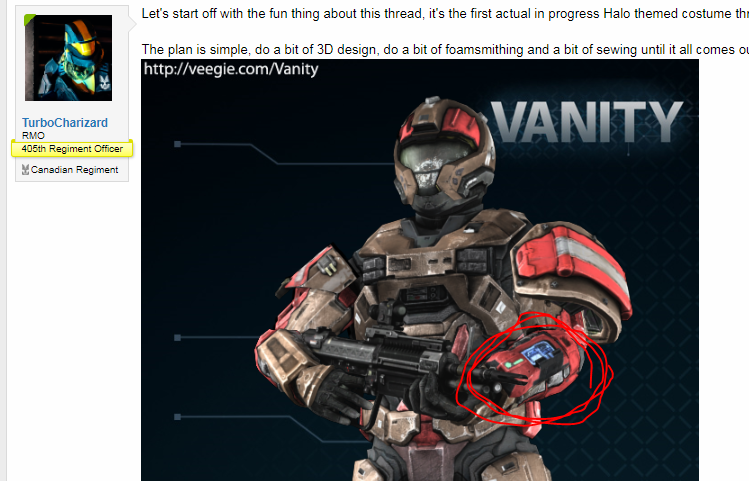

A few things have changed slightly with the build such as visor colour but I want me my Tactical Bracer! Reference photos for it in relatively high definition were rather hard to come by but thankfully with the powers of Google Image Search there was an HD screenshot of the punching animation which I'd never have been able to snag easily on my own. The First Person arms are higher definition than the if you look at another players model so using a few different images I was able to piece together a fairly close approximation to the wrist mounted computer.

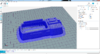

When building the original left gauntlet I left a convenient flat section to mount the bracer to at some later point and that time is now(ish). The TacPad is a flat mounting plate which pressure fits into the cover and has recesses for eight 5mm diameter 2mm depth N35 magnets. There is two transparent covers for the green indicators and four button posts to extend to the internal electronics.

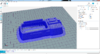

Everything was printed using a mix of eSun PLA+ from filaments.ca between the two printers for the body pieces and and Spool3D Transparent PLA for the diffusers. Inside the TacPad is a FN-BC04-TB MP3 board, four momentary switches to act as triggers and a EBL 6F22 9V rechargeable battery. Also powered by this battery will be two 5mm green LEDs for the indicators and two 5mm blue LEDs for the display panel back light.

Once everything is painted and wired up I'll post a video of the silly sound effects in action. If you go back into the depths of this thread there's hints to at least one of them. Happy hunting!

I'm currently working on a few different projects so things being finished up is a bit of a pipeline process meaning that you'll likely get a whole whack of posts once paint gets slapped down on all the shiny new parts. Anyone who is paying attention to my Instagram knows how much hype I've had for one very shiny new part and I can't wait for that novella of a post in the near future.

Who here remembers what was going on way back in that first post? Honest answers only! There's been one major piece missing from my armour somewhere in this area.

A few things have changed slightly with the build such as visor colour but I want me my Tactical Bracer! Reference photos for it in relatively high definition were rather hard to come by but thankfully with the powers of Google Image Search there was an HD screenshot of the punching animation which I'd never have been able to snag easily on my own. The First Person arms are higher definition than the if you look at another players model so using a few different images I was able to piece together a fairly close approximation to the wrist mounted computer.

When building the original left gauntlet I left a convenient flat section to mount the bracer to at some later point and that time is now(ish). The TacPad is a flat mounting plate which pressure fits into the cover and has recesses for eight 5mm diameter 2mm depth N35 magnets. There is two transparent covers for the green indicators and four button posts to extend to the internal electronics.

Everything was printed using a mix of eSun PLA+ from filaments.ca between the two printers for the body pieces and and Spool3D Transparent PLA for the diffusers. Inside the TacPad is a FN-BC04-TB MP3 board, four momentary switches to act as triggers and a EBL 6F22 9V rechargeable battery. Also powered by this battery will be two 5mm green LEDs for the indicators and two 5mm blue LEDs for the display panel back light.

Once everything is painted and wired up I'll post a video of the silly sound effects in action. If you go back into the depths of this thread there's hints to at least one of them. Happy hunting!

I'm currently working on a few different projects so things being finished up is a bit of a pipeline process meaning that you'll likely get a whole whack of posts once paint gets slapped down on all the shiny new parts. Anyone who is paying attention to my Instagram knows how much hype I've had for one very shiny new part and I can't wait for that novella of a post in the near future.